TZ-750B Servo Plastic Cup Making Machine

1, Lead Time:1-2 months after deposit confirmed

2, Price Term: FOB,EXW,CFN,CIF,etc.

3,Payments: T/T,Visa,Paypal,etc.

What Is A Plastic Cup Making Machine?

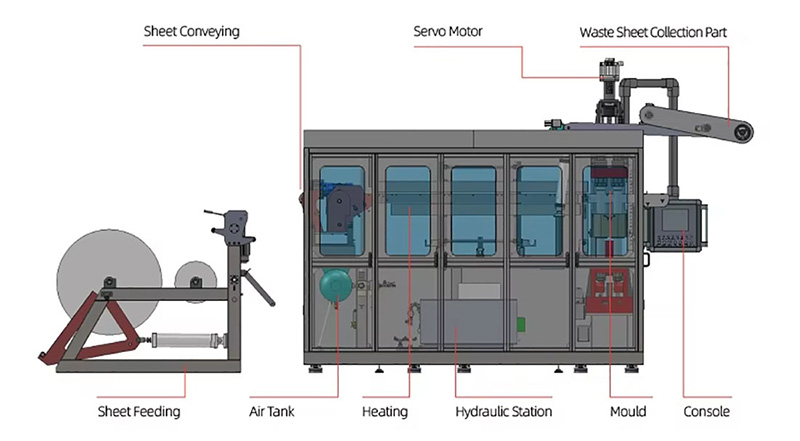

TZ-750B fully automatic servo plastic cup making machine is designed to produce cup shape products. Such as disposable plastic cup, bowls, plates, lids, etc. This plastic cup thermoforming making machine have high productin efficiency with its forming and cutting two-in-one station. Controlled by microcomputer, this cup thermoforming machine can completes the plastic cup production at one time by conveying, heating, forming and cutting, and sheet waste winding.

TZ-750B servo plastic cup thermoforming machine is suitable for thermoforming of PP, PS, PET, PVC and other plastic sheets. Professional in producing all kinds of cup shape products, such as disposable plastic bowls, plastic plates, plastic water cups, disposable coffee cups, milk tea cups, plastic cup, plastic lids, plastic jelly cups, etc.

The Principle Of Plastic Cup Forming:

Thermoplastic plastic sheets are heated and placed on the mold. A plunger stretches the sheet, while compressed air presses it against the mold cavity to form the product. After the cutting process, the finished product is automatically ejected.

Mold: The mold integrates functions such as pressing, forming, cutting, cooling, and product ejection into one unit.

Functional Characteristics Of Our Servo Plastic Cup Machine?

- Fully servo-driven, silent, vibration-free, excellent thermoforming, and high speed.

- Compact design, occupying minimal floor space.

- Integrates sheet feeding, heating, stretching, forming, and trimming in one process.

- Automatic unloading device allows adjustable production parameters without material waste.

- One-to-one intelligent temperature control system in the electric furnace for even heating, energy efficiency, rapid temperature rise, and three low-temperature baking cycles.

- Servo-driven forming and cutting molds with bi-directionally adjustable stroke; the upper mold’s closing direction is electrically adjustable for easy height adjustments and faster, vibration-free operation.

- PLC for automatic cutting, counting, and transportation.

- Only 1-2 operators needed for packing.

Main Function:

- Positive and negative pressure forming device.

- Vacuum forming device.

- Touch screen computer with point-to-point temperature control functionality.

- Air control system.

- Cooling system.

- Mold and mold temperature control features.

- Automatic punching and cutting function.

- Automatic stacking and counting feature.

- Automatic scrap winding function (can be equipped with an online crusher).

- Safety protection device.

PP PS PET PVC Cup Machine Parameters

| Model | TZ-750B | TZ-850B |

| Forming Method | Positive And Negative Pressure Forming | |

| Mould Size (Max.) | 750*420mm | 850*550mm |

| Forming Depth (Max.) | ≦220mm(Normal≦180mm) | ≦220mm(Normal≦180mm) |

| Sheet thickness: | 0.2-3.0mm | 0.2-3.0mm |

| Forming Speed (Max.) | 28times/min | 28times/min |

| Air pressure | 0.6-0.8mpa | 0.6-0.8mpa |

| Sheet width (Max.) | 550-790mm | 650-890mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA | PP, PS, HIPS, PET, PVC, PLA |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire | AC 380V, 50Hz, Three-phase, Four-wire |

| Heating Area | 135KW | 147KW |

| Rated power | 165Kw | 182Kw |

| Procedure | Forming-punching-cutting | Forming-punching-cutting |

| Weight | 8T | 9T |

| Dimension | L4800*W1500*H2500mm | L5200*W1600*H2500mm |

| Main Electrical Components | ||

| MODEL/PARTS | TZ-750B | TZ-850B |

| Touch Screen | KUNLUN TONGTAI(CHINA) | KUNLUN TONGTAI(CHINA) |

| PLC | Siemens | Siemens |

| Servo pack | Inovance | Inovance |

| Servo Motor | Inovance | Inovance |

| Heater | ELSTEIN(Germany) | ELSTEIN(Germany) |

| Temperature control module | Yamatake Temperature Control system (Japan) | Yamatake Temperature Control system (Japan) |

| Solenoid Valve | CKD(Japan) | CKD(Japan) |

| Solid State Relay | (OMRON) | (OMRON) |

| Circuit Breaker | SCHNEIDER(France) | SCHNEIDER(France) |

| AC Contactor | SCHNEIDER(France) | SCHNEIDER(France) |

| Power switch | SCHNEIDER(France) | SCHNEIDER(France) |

Production Processing:

Taizhang provide complete plastic cup making production line solution from plastic sheet extrusion – plastic cup thermoforming – stacking – plastic cup counting & packaging.

Customers Also Inquire Corollary Machines

Cup-making Machine Online Crusher

Cup-making Machine Manipulator

Automatic Plastic Cup Stacking Machine

Auto Plastic Cup Counting & Packaging Machine

Equipment Details:

PLC Control: Siemens PLC for accurate performance and recipe storage.

Mold Guide Columns: Stable four-column design (40R steel, hard chrome plated) for durability and high accuracy in mold operation.

Temperature Control: PID regulation with Taiwan Yangming modules; temperature deviation within ±1 degree across 20 channels.

Sheet Feeding Chain: Double-row roller chain with teeth, supported by quenched 40Cr guide rails for enhanced durability.

Hydraulic System: Joint-venture oil pump with imported electromagnetic valves from Taiwan.

Heater: Tianbao curved electric heating tiles for high efficiency and safety.

Servo Stretching: Huichuan servo motors control mold speed for uniform strength and consistent bottom thickness, optimizing material usage.

Accessories: Air circuit control with AIRTAC cylinders, utilizing reliable Japanese and Taiwanese components for longevity.