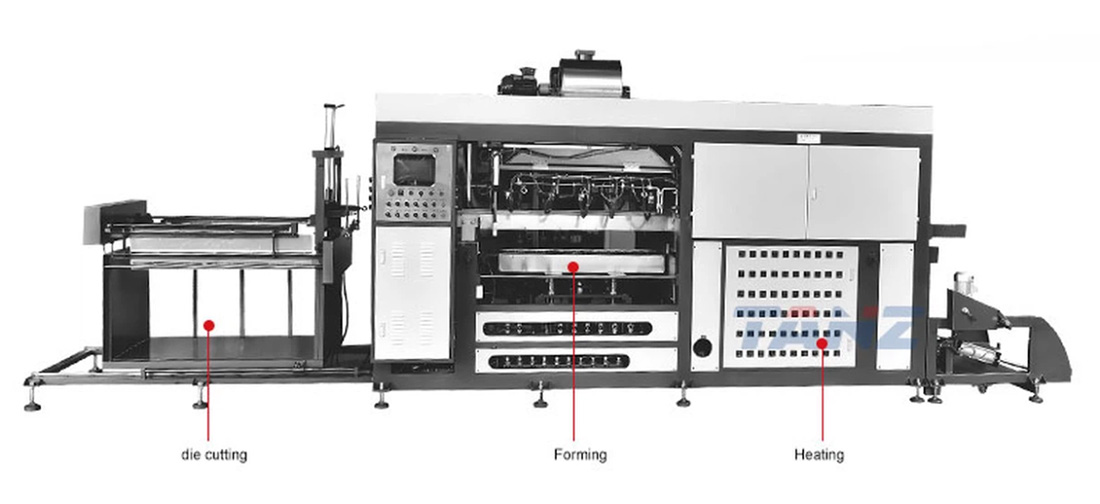

Thermoforming Machines

Proven technologies, complete solution, rich experience, fully-automatic, semi-automatic, three/four stations; Produce food container, fruit packaging boxes, egg trays, seedling trays, electronic trays, food trays, clamshell, etc.

TZ-1220F High Speed Servo Thermoforming Machine Form Area 760x1220mm

TZ-1220F semi-auto high speed servo thermoforming machine, the upper and lower molds are driven by servo motors at constant speed. can ensure the high precision of product stretching and forming. Suitable for large size products. Forming molds can be plaster mold, copper mold, and aluminum mold. flexible for product production.

1, Lead Time:1-2 months after deposit confirmed

2, Price Term: FOB,EXW,CFN,CIF,etc.

3,Payments: T/T,Visa,Paypal,etc.

What 's The Function Features Of TZ-1220F Thermoforming Machine:

1, High speed servo thermoforming mahcine: Its upper and lower molds are driven by servo motors at constant speed, it ensures high precision of product stretching.

2, Adopting servo drive and full computer PLC control, it has storage memory and correction functions (accuracy ± 1mm), as well as sheet exit function to avoid sheet waste. The feeding adopts automatic design;

3, To match the molding of different materials, the vacuum displacement adopts a dual body and valve complementary design, ensuring stretchability and rapid molding of difficult products;

4, To ensure the forming stability of products with different rules, demolding is equipped with upper mold, top mold repetition, or multiple frequency modes to choose from;

5, The electric furnace adopts a closed horizontal reciprocating design, and the temperature control adopts constant pressure independent control. The heating is stable and the replenishment is uniform, which can effectively solve the problem of PET materials whitening, deformation and other adverse waste phenomena, saving more than 40% of electricity;

6, The cooling device and rapid cold water spray are increased, and the auxiliary demoulding spray function is set to accelerate the production speed, and the efficiency is more than 40% faster than the traditional machine;

Scope Of Application:

TZ-1220F semi-auto high speed servo thermoforming machine is suitable for molding thermoplastic materials, such as PS HIPS, PVC, PET, PP, PE, PS, KPS, GPET, ABS with a thickness of 0.15-3.0mm. Processing high transparency, high stretch, round, square, irregular, up and down bidirectional Stretch, flange products.

It is widely used in the sealing packaging of toys, hardware, cosmetics, electronic products (such as batteries, electronic components, etc.), food (such as fruit trays, snack boxes, biscuit boxes, food trays, trays, etc.), medicines, etc.

Food Packaging Box

Fruit Packaging Box

Clamshell

Egg trays

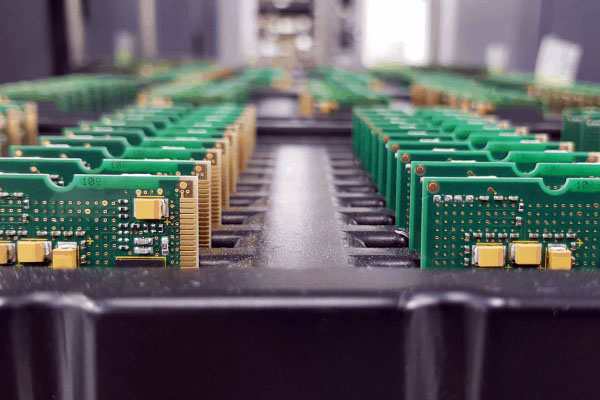

Electronic Trays

Seedling Trays

Meat Packaging Box

Food Trays

Technical Parameters:

| Model | TZ-1220F Semi-auto Servo Thermoforming Machine |

| Forming Method | Negative pressure forming |

| Mould Size (Max.) | 760*1220mm |

| Forming Depth (Max.) | 180mm |

| Sheet thickness: | 0.16-2.0mm |

| Forming Speed (Max.) | 6-15times/min |

| Air pressure | 0.6-0.8mpa |

| Sheet width (Max.) | 490-750mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire AC 380V,50Hz |

| Heating Power | 39KW |

| Rated power | 55Kw |

| Procedure | Forming |

| Weight | 4.8T |

| Dimension | L105000*W2150*H2800mm |

Main Electric Componients:

| MODEL/PARTS | TZ-1220F |

| Touch Screen | KUNLUN TONGTAI(CHINA) |

| PLC | Siemens |

| Servo pack | Inovance |

| Servo Motor | Inovance |

| Heater | ELSTEIN(Germany) |

| Temperature control module | Yamatake Temperature Control system (Japan) |

| Filter | CKD(Japan) |

| Solenoid Valve | CKD(Japan) |

| Solid State Relay | OMRON (Japan) |

| Proximity Switch | OMRON(Japan) |

| Circuit Breaker | SCHNEIDER(France) |

| AC Contactor | SCHNEIDER(France) |

| Power switch | Fuji(Japan) |