Table of Contents

Received Seedling Trays Making Machine Inquiry:

Plastic seedling trays making machine, in October 2023, we had the privilege of receiving an inquiry from Turkish client Mr. Erdoğan. Through our website, he expressed interest in purchasing a dedicated production line for plastic seedling trays.

Details Of Customer Seedling Trays:

Mr. Erdoğan provided detailed specifications for the seedling trays: dimensions of 21×11 inches, with hole counts of 28, 32, and 50, and depths of 65mm, 55mm, and 45mm. The trays are to be produced using high-quality PVC with a perforated design for optimal water and air circulation.

TZ machinery Seedling Trays Making Machine Solution:

Fully-auto Seedling Tray Thermoforming Machine solution:

A fully automatic four-station positive and negative pressure thermoforming machine (forming station, hole punching station, cutting station, stacking station). This solution offers high capacity and automation, significantly reducing labor costs and lowering unit production costs, with an estimated price of $128,000.

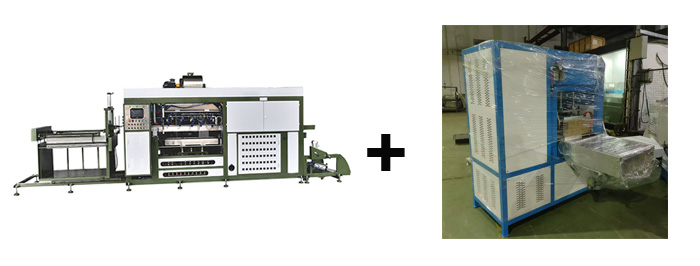

Semi-auto Seedling Trays Macking Machine +Separate cutting and pouching machine:

A semi-automatic high-speed seedling trays making machine combined with a cutting and punching machine. The capacity is lower relatively and requires manual cutting and punching. Therefore this solution cam make it suitable for a smaller initial investment, with an estimated cost of $60,000.

Customer Chose Seedling Trays Making Solution:

After careful consideration and market analysis. Two month later, Mr. Erdoğan chose the semi-automatic thermoforming machine and cutting/punching solution. This solution for his initial operations to minimize startup costs while allowing for future scalability. He indicated plans to invest in the fully automatic system as business grows.

We look forward to establishing a long-term partnership with Mr. Erdoğan and supporting his success in the plastic seedling tray market!