Table of Contents

Why Is TZ Solution Better Than It Made In Turkey And Germany?

TZ machinery PET sheet extrusion solution is different from it made in Turkey and Germany, although we are all single screw PET sheet extrusion line. The key difference are as bellow:

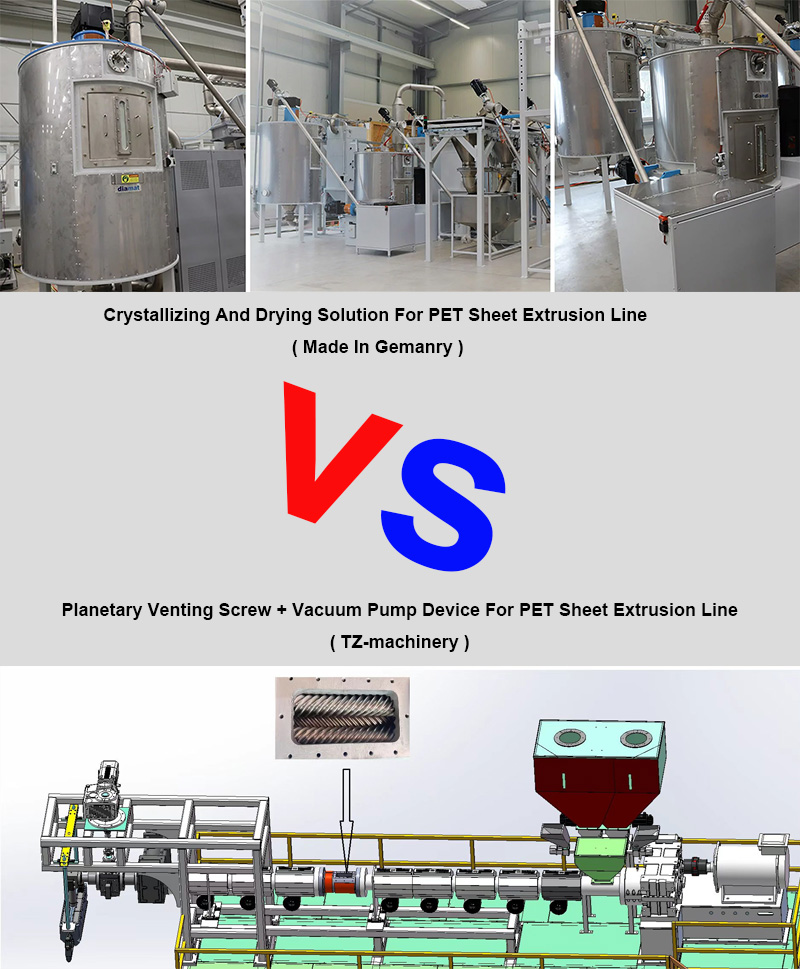

1, Germany PET material Treatment Solution:

Germany And Turkey adopt separate crystallizing tower and drying tower solution. They treat the PET pellets and PET flasks before start producing. Their PET sheet production line can produce PET sheet With Pure material and 100% recycling materials. But crystallizing and drying equipment need high investment, more labor to operate and consume more power.

2, TZ-machinery PET materials Treatment Solution:

TZ PET sheet extrusion production adopt the design of planetary venting screws and vacuum pump device. Automatic, save energy, easy to operate and save labor.

During the processing of PET, especially in the high-temperature molten state. volatile substances may be generated, such as moisture and low molecular weight compounds. The planetary vent screw effectively removes these gases, thereby preventing them from affecting the quality of the final product;

Uniform Mixing: The unique structure of the screw enables uniform mixing of the material in the molten state. ensuring consistency in the extruded material, which enhances the uniformity and quality of the final product.

Increased Yield and Efficiency: By facilitating effective gas removal and mixing, the planetary vent screw boosts processing efficiency, thereby accelerating production speed and increasing yield.

Temperature Control: The design of the planetary vent screw helps maintain better temperature distribution. preventing overheating or uneven temperatures that could lead to material degradation.

What Are The Principles Of TZ Single Screw PET Sheet Extrusion Line?

Structural Design:

TZ machinery single screw PET sheet extrusion line is with planetary vent screw, which typically consists of multiple screws and one venting ports. During the extrusion process, the material is pushed forward by the screw while its rotation creates complex flow patterns.

Material Conveying and Extrusion:

The material is continuously compressed, heated, and mixed within the screw’s helical channels, while gases are forced along a specific path toward the venting ports.

Gas Removal Mechanism:

In specific areas of the extruder, a vacuum or compression system aids in extracting or pushing out the generated gases using negative pressure, ensuring the purity and stability of the material in its molten state.

Temperature and Pressure Control:

The design considers variations in temperature and pressure to ensure that the material is melted and extruded under suitable conditions, protecting the properties of the PET.