What Is The Difference Of Thermoforming & And Injection Molding?

Thermoforming and injection molding are two popular plastic manufacturing processes, each with unique advantages.

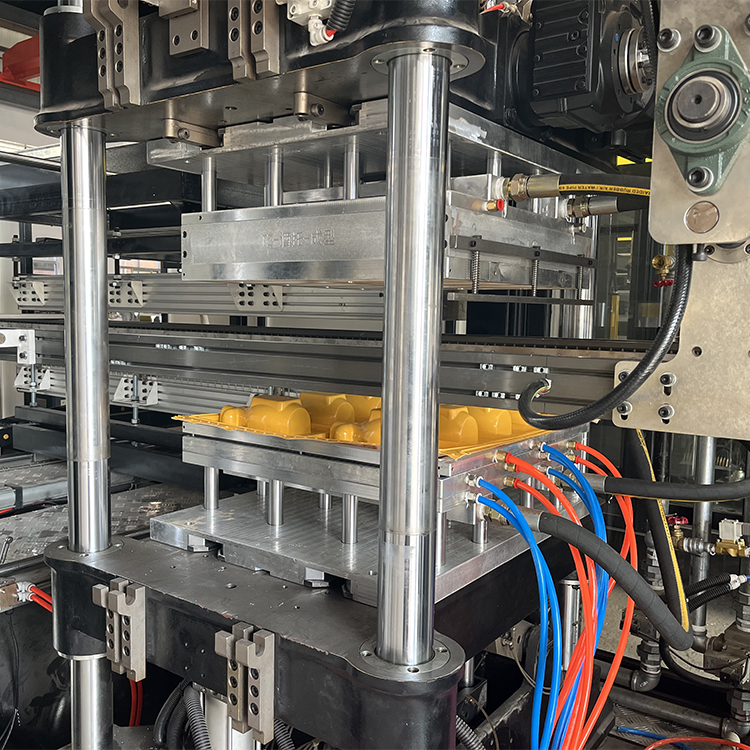

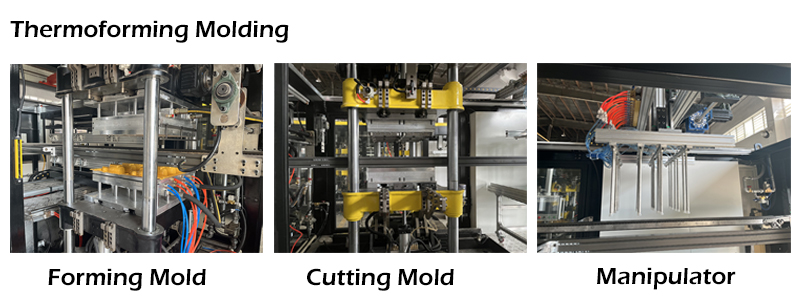

Thermoforming:

Thermoforming involves heating a plastic sheet until pliable, then shaping it using a thermoforming mold and trimming it to create the final product. This method is cost-effective for large parts and short runs, making it ideal for packaging, trays, and automotive components. Plastic thermoforming machines are versatile and require lower tooling costs compared to injection molding.

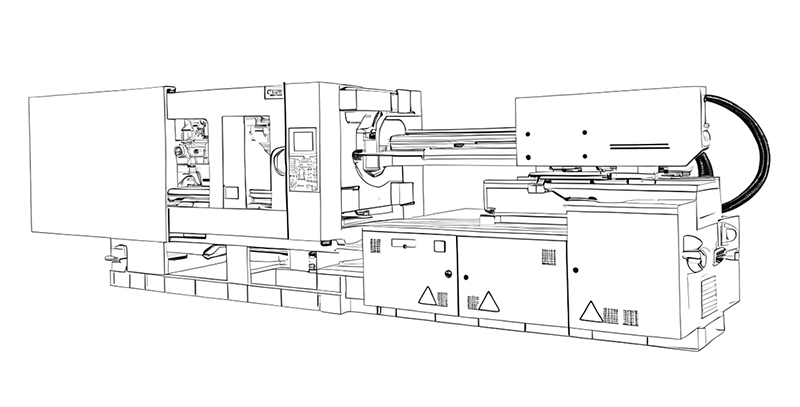

Injection Molding:

Injection molding, on the other hand, injects molten plastic into a mold under high pressure, producing highly detailed and durable parts. It’s perfect for high-volume production of complex components like gears and enclosures. While injection molding offers precision and repeatability, thermoforming excels in affordability and flexibility for simpler designs.

Choosing between the two depends on your project’s needs: thermoforming for cost-efficiency and larger parts, or injection molding for intricate, high-volume production. Explore thermoforming molds and plastic thermoforming machines to find the best solution for your manufacturing goals.