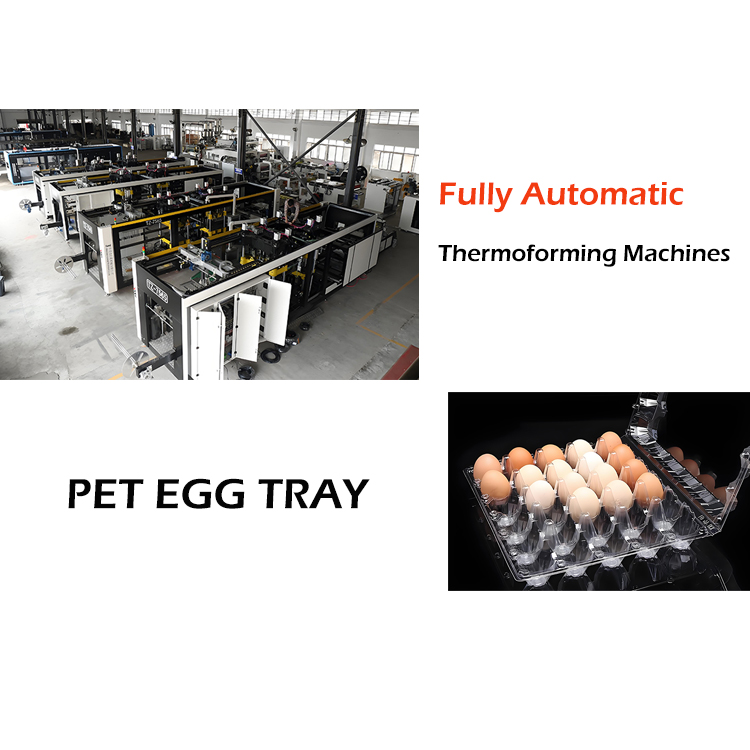

Why Use Positive and Negative Pressure Thermoforming Machines for Egg Trays?

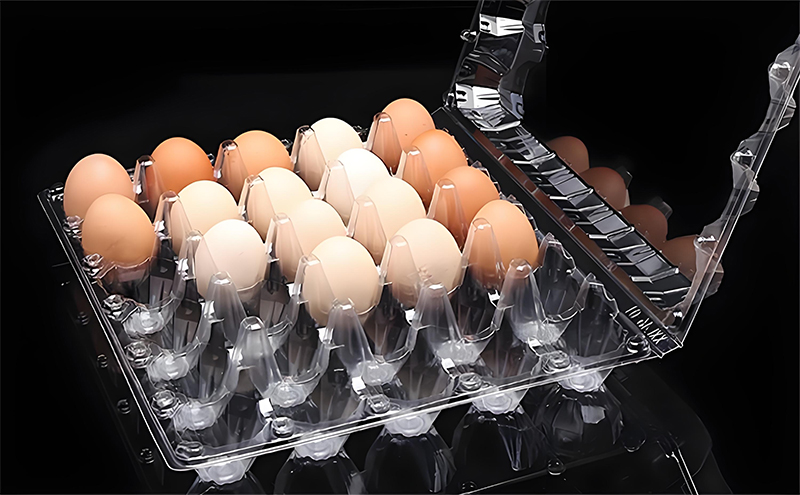

To find a fully automatic egg tray making machine, need to understand: Egg trays feature intricate designs with internal support structures and snap-fit mechanisms to securely hold fragile eggs. These complex shapes demand precise molding techniques to ensure durability, ventilation, and shock absorption. Traditional methods often struggle to achieve the fine details required for optimal egg protection, making advanced thermoforming technology essential for high-quality production.

The 3-Station Positive/Negative Pressure Machine de thermoformage excels at crafting intricate egg trays with unmatched efficiency. By combining vacuum suction and air-pressure forming in one system, it ensures uniform material distribution, sharp edge definition, and consistent wall thickness. This dual-pressure process allows for complex geometries like reinforced ribs and interlocking tabs, while maintaining ±0.5mm precision. For egg tray manufacturing, this machine guarantees smooth surfaces to prevent egg abrasion and robust structures to withstand stacking—critical for both small farms and industrial-scale poultry operations.

Looking for a reliable machine de fabrication de plateaux d'œufs? Our egg tray thermoforming machine integrates automation and energy-saving features, reducing labor costs and material waste by up to 30%. Equipped with customizable molds, it adapts to various tray sizes and eco-friendly materials (pulp, recycled PET). Contact us today to optimize your egg packaging line with precision-engineered solutions!