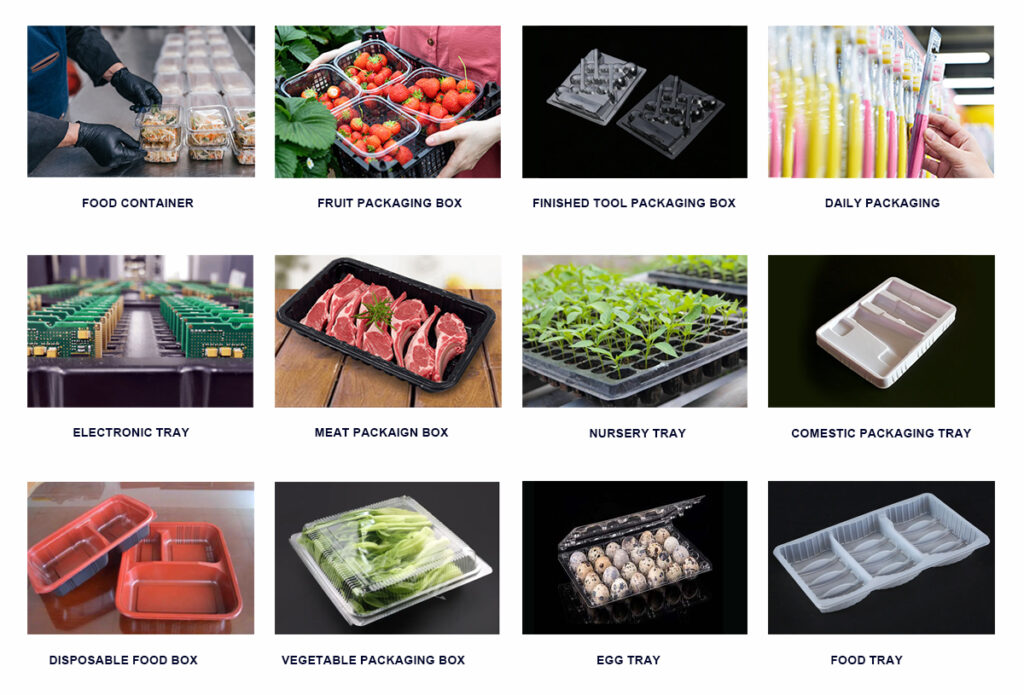

A mesin thermoforming is designed to produce all kinds of thermoforming packaging products. Such as plastic food container, PET fruit container, biscuit trays, egg trays, cosmetic packaging trays, fast food boxes, seedling trays, disposable plates, electric product trays, etc.

TZ Thermoforming Machines Categories:

Semi-automatic Thermoforming Machines:

negative pressure forming process, only have forming station. Cutting need extra cutting machine to acheive, stacking need to be done manually.

Fully-automatic Thermoforming Machines:

Integrated design: unwinding-conveying-heating-forming-(hole pouching)-cutting-stacking-sheet scrap winding; include negative pressure thermoforming machines and positive-negative pressure thermoforming machines.

1. Negative pressure thermoforming machines are slower, but forming area is big; quick mold change; point to point temperature control, save power consumption; save labor cost.

2. Positive-negative pressure thermoforming machines are faster; forming area is small relatively; quick mold change; point to point temperature control, save power consumption; save labor cost.