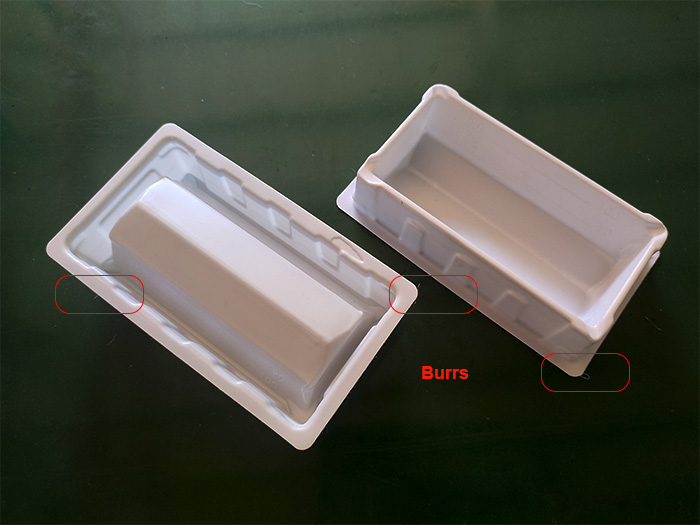

What if The products cut out by cutting die of the thermoforming machine have burrs?

When thermoforming products from the thermoforming machine cutting station have burrs, take these measures:

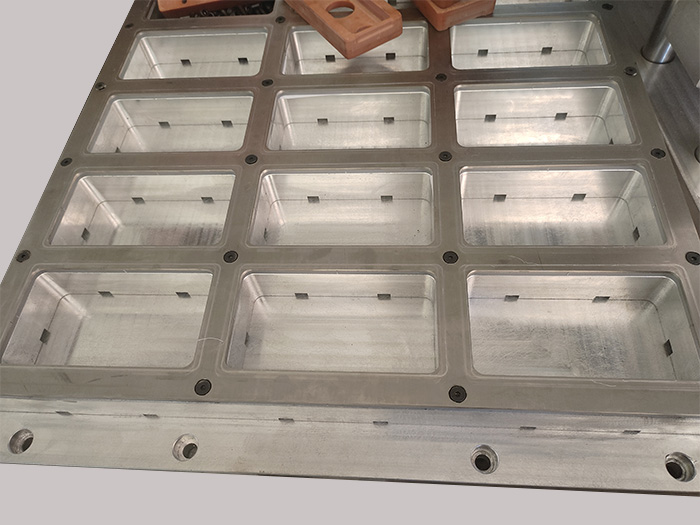

Optimize Die Design Of Thermoforming Machine:

Check the die design for sharp edges and smooth shapes. Avoid sharp corners to reduce burrs.

Adjust Cutting Temperature:

Set the die heating temperature correctly. Increase temperature if the cuts appear incomplete.

Control Cutting Speed:

Adjust the cutting speed for better results. Slower speeds usually prevent burr formation.

Increase Cutting Pressure:

Verify and increase the cutting pressure as needed. Higher pressure improves contact with the material.

Choose Quality Materials:

Select materials with good cutting characteristics. Avoid materials that create excessive burrs.

Implement Post-Processing:

Use trimming and grinding for finished products. Mechanical or manual methods can smooth edges effectively.

Maintain the Die Regularly:

Inspect and maintain the die frequently. Regular sharpening keeps the cutting edge effective.

Perform Test Cuts:

Conduct small-scale test cuts before full production. Adjust parameters based on the test results.

Applying these measures reduces burrs and improves thermoforming product quality from the mesin thermoforming.