THERMOFORMING MACHINES

プラスチックカップ製造機

エキスパートへのお問い合わせ

適切な熱成形機を選ぶには?

Dear Customers:

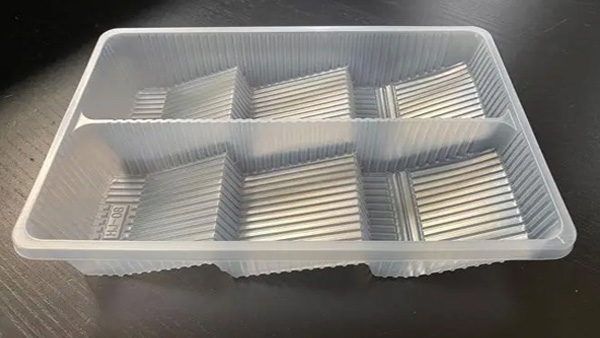

Thank your for visiting our thermoforming machine solution page. TZ-machinery has semi-auto thermoforming machine solution, fully automatic integrated thermoforming machine solutions and plastic cup thermoforming machine solution.

It’s very necessary to know the difference of all thermoforming solutions before you make decision to use our machine solution to meet your production requirements.

Below are fast guides for your reading.

Best rgds

TZ-machinery group

SEMI-AUTO

SEMI-AUTOMATIC

INTEGRATED

FULLY-AUTO

INTEGRATED

FULLY-AUTO

INTEGRATED

FULLY-AUTO

Plastic Cup Machine

Plastic Cup Machine

Plastic Cup Machine

Plastic Cup Machine

Advantages Of Integrated Fully-auto Thermoforming Machines:

Quick Mold Change

Quick Mold Change

Point To Point

Heating Temperature Control

Mold Cost Budget For Reference Of Integrated Thermoforming Machine:

Plaster Mold

USD70 ~ USD120/set, based on the exact product design. For sample making.

Copper Mold

USD1300 ~ USD1600/set, based on the exact product design. For small customized order.

Aluminum Mold

USD5000 ~ USD7200/set, based on the exact product design. For big quantity order.

Last But Very Important For Your Decision Making:

1, Determine The Specification And Shape Of Ther Thermoforming Products:

熱成形する製品によって、必要な熱成形機の仕様や形状が異なります。そのため、熱成形機を選ぶ際には、まず生産する熱成形品の仕様や形状を明確にする必要があります。

2、出力と生産時間を決定する:

熱成形機を選ぶ際には、生産する製品の数と生産時間を決めて、熱成形機の生産能力と生産効率を見極め、自分に合った熱成形機を選ぶ必要がある。

3、成形精度:熱成形機の成形精度は製品の品質に重要な影響を与えるため、装置の成形精度を考慮する必要がある。

熱成形機は半自動と全自動に分けられる。

高速サーボ成形機(半自動)、全自動3・4ステーション負圧熱成形オールインワンマシン、全自動3・4ステーション正・負圧熱成形オールインワンマシンに分けられます。

高速サーボ成形機(半自動):より大きなサイズとより多くの製品タイプの製品に適しています。成形金型は石膏型、銅型、アルミ型を選択でき、製品生産に融通が利きます(TZ-1220F)。

全自動3/4ステーション負圧熱成形機成形-パンチング-パンチング-スタッキング、完全自動統合生産、低エネルギー消費、省力化、成形金型は、ほとんどの顧客(TZ-7695)の生産ニーズを満たすために、石膏型、銅型、アルミ型を選択することができます。

全自動3/4ステーション負圧熱成形機成形-パンチング-パンチング-スタッキング、全自動一貫生産、低エネルギー消費、省力化、高出力、強い三次元感覚を持つ成形品、均一な厚さ、成形金型のみアルミ金型にすることができ、大規模な受注生産に適しており、製品の品質と出力に高い要求を持つ顧客(TZ-7385、TZ-7265)。

より多くの細部については、pls は左の形態から私達にあなたの照会を送ります。または私達の専門家への whatsapp、私達はあなたにできるだけ早く答えます。