Plastic Sheet Extrusion Line Solutions

PET sheet extrusion machine, PP/PS sheet extrusion line, PP PS PE multi-layer co-extruded sheet production line, PLA sheet extrusion line. Single Screw, parallel exhaust type twin screws, planetary screws section (do not need crystallizing & drying)

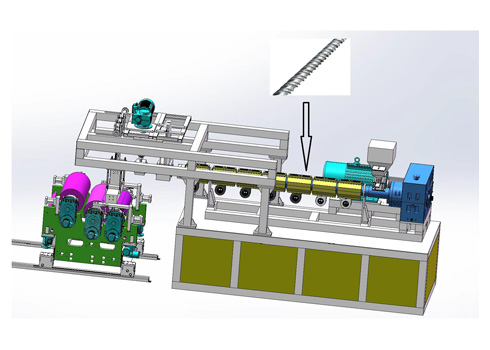

PP PS Sheet Extrusion Machines

The screw is from Taiwanese Technology, have the advantages of forced feeding, fast speed, high production capacity and good quality. This sheet extrusion line is designed to produce PP sheet, PS sheet, single layer sheet, multi layers co-extruded sheet.

1, Lead Time:1-2 months after deposit confirmed

2, Price Term: FOB,EXW,CFN,CIF,etc.

3,Payments: T/T,Visa,Paypal,etc.

Table of Contents

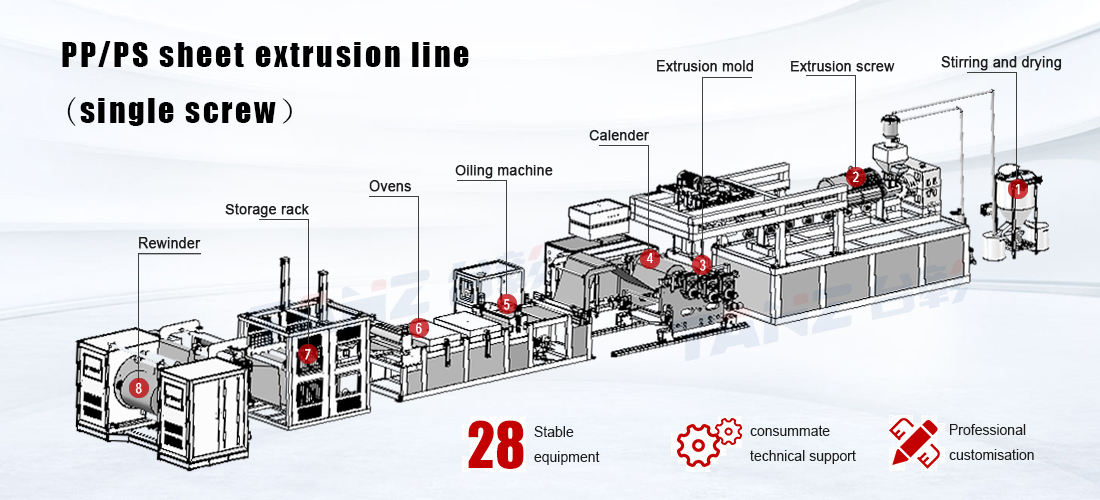

The Functional Features Of PP/PS Sheet Line:

The screw is from Taiwanese Technology, has the advantages of forced feeding, high speed, high production capacity and good quality.

What Can A PP/PS Sheet Extruder Machine do?

According to different product requirements, this PP/PS extrusion production machine can produce single layer sheet, two-layer co-extruded sheet, multi-layer extruded sheet. Widely used in the fields of food packaging, stationery packaging and other plastic packaging. There are transparent PP sheet, frosted sheet, two-color sheet, etc.

Equipment Parameters:

- Mixing-drying Machine

- Ration Feeder

- Masterbatch Mixer

- Extruder Screw

- Hydraulic Filter Changer

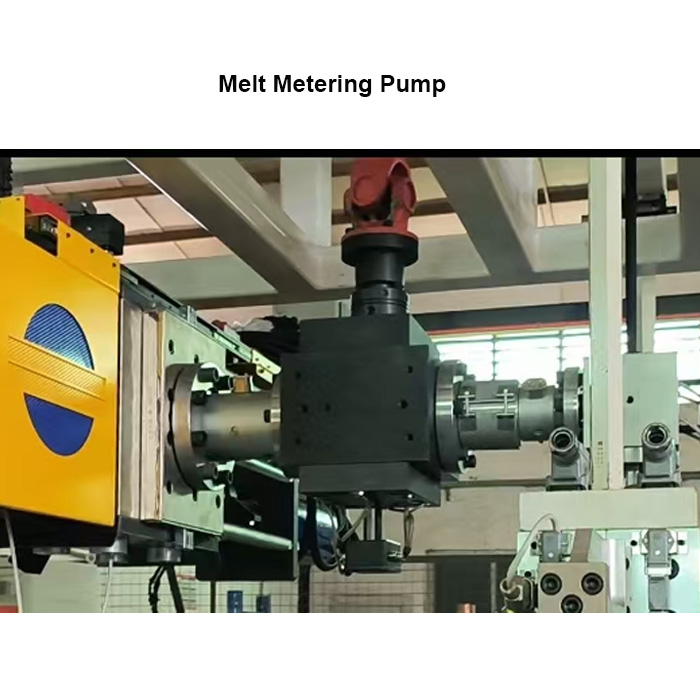

- Metering Pump

- Mould

- Three-roll Calender

- Calender Temperature Control System

- Waste Edge Cutting Device

- On-line Crusher of Waste Edge Material

- Oil Coating Device

- Oven

- Traction Machine

- Storage Rack

- Automatic Winder

Technical Parameters:

| Model | Aplicable Materials | Screw specifications | Sheet thickness (mm) | Sheet width (mm) | Maximum extrusion output (kg/h) | Installed capacity (KW) |

|---|---|---|---|---|---|---|

| TZNZ-100PP | PP,PS,PE | Φ100 | 0.2-2.0 | ⩽850 | PP:350KG PS:400KG | 210 |

| TZNZ-120PP | PP,PS,PE | Φ120 | 0.2-2.0 | ⩽850 | PP:450KG PS:550KG | 250 |

| TZNZ-150PP | PP,PS,PE | Φ150 | 0.2-2.0 | ⩽850 | PP:800KG PS:900KG | 350 |

| TZNZ-120/65PP | PP,PS,PE | Φ150 | 0.2-2.0 | ⩽850 | PP:550KG PS:600KG | 460 |

| TZNZ-150/70PP | PP,PS,PE | Φ150 | 0.2-2.0 | ⩽850 | PP:850KG PS:900KG | 550 |

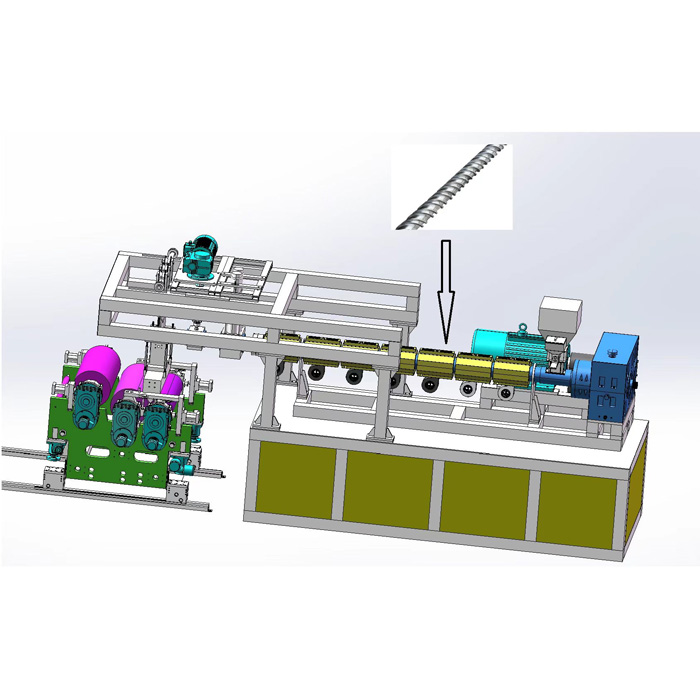

PP/PS Sheet Extrusion Line Details:

Extruder

It is derived from Taiwan’s technology design, has the advantages of forced feeding, speed, high production capacity and good quality. screw option: single screw, parallel two screws.

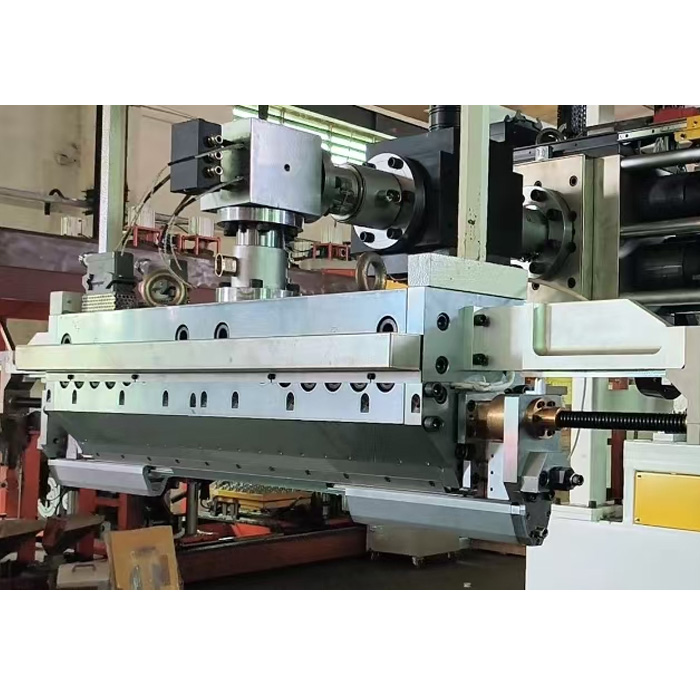

Mould

The mold is made of alloy steel, and the flow channel is chrome-plated and polished, allowing the mold width to be adjusted without stopping the machine.

Three-roller calender

The three-roller light machine is a horizontal or vertical or 45 degree inclined design.The thickness of the sheet is automated adjustment system,The machanical roller has anti-collision protection function.The use of electronic hand wheel operations to implement the sheet specifications,which are transformed quickly and relaxed,and no tedious operations are required.The accuracy of slices is as high as 0.005mm.

Two Station Winder

The dual station winding machine is equipped with automatic meter meter , You can also customize a larger volume weight , and the larger diameter can be collected by 1.15 meters . It also specially developed an automatic winding machine that can collect 2 rolls at the same time to achieve high production capacity.