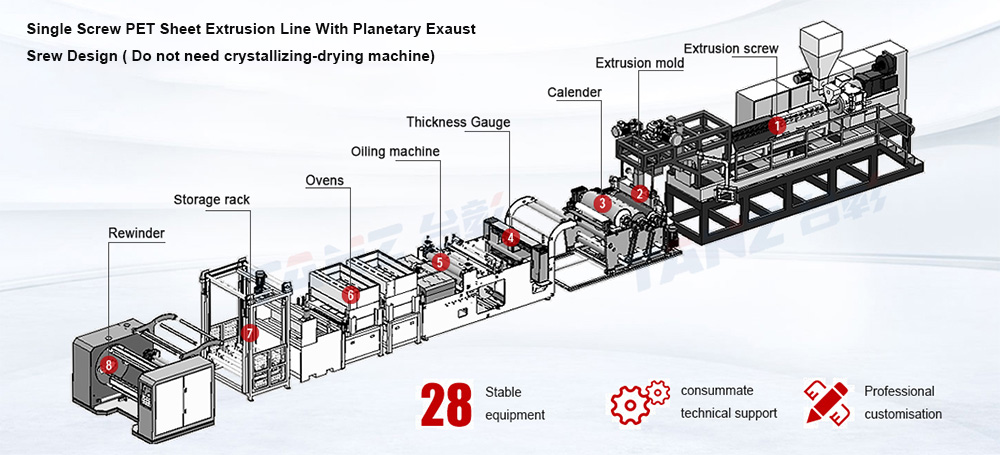

Plastic Sheet Extrusion Line Solutions

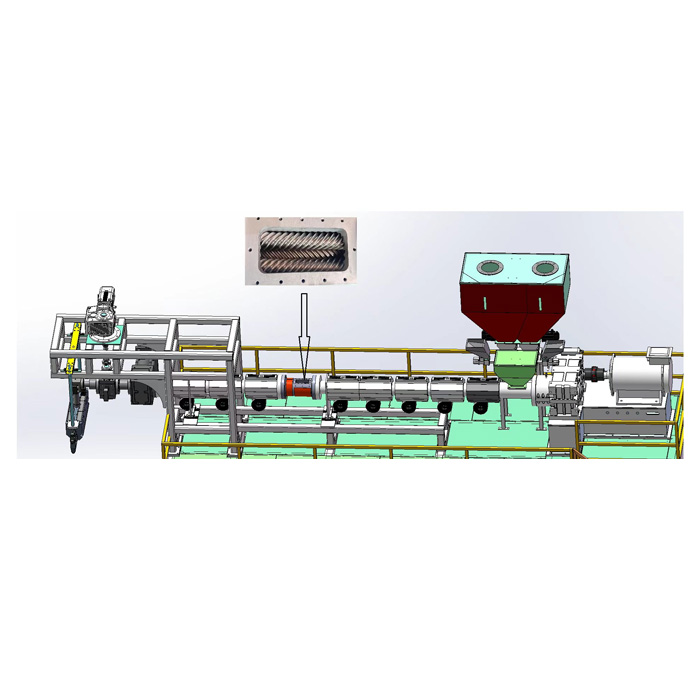

PET sheet extrusion machine, PP/PS sheet extrusion line, PP PS PE multi-layer co-extruded sheet production line, PLA sheet extrusion line. Single Screw, parallel exhaust type twin screws, planetary screws section (do not need crystallizing & drying)

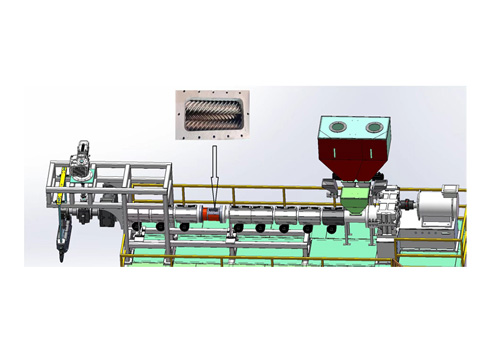

Single Screw PET Sheet Extrusion Production Line

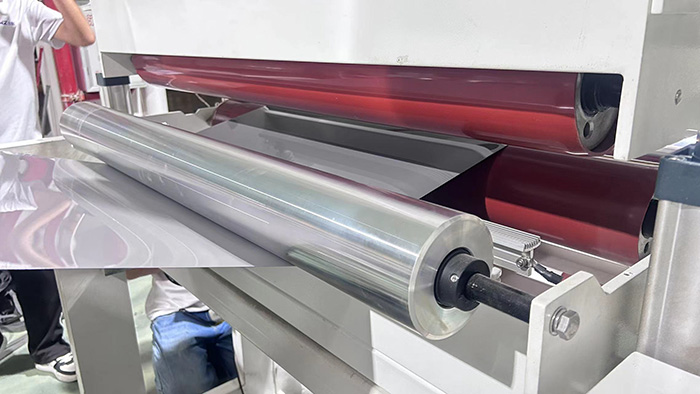

The forming part of the pressure roller is made of alloy steel with different thermal conductivity. Through special manufacturing technology and heat treatment process.

1, Lead Time:1-2 months after deposit confirmed

2, Price Term: FOB,EXW,CFN,CIF,etc.

3,Payments: T/T,Visa,Paypal,etc.

Function Features Of TZ Single Screw PET Sheet Extrusion Production Line:

1.Adopt Taiwan’s independently developed high-speed and high-capacity planetary exhaust screw. Do not need the crystallizing and drying towers to pretreat the PET materials. Can do recycling materials.

2. The forming part of the pressure roller is made of alloy steel with different thermal conductivity. Through special manufacturing technology and heat treatment process, the temperature of the roller is uniform, the heat dissipation speed of the rod surface is fast, the material does not stick to the roller, and the product molding speed is fast, which is suitable for high production capacity and high quality applications.

3.The thickness adjustment of the colliding machine sheet adopts an automatic adjustment system, and the mechanical roller has anti-collision protection function.

4.Electronic handwheel operation is used to achieve quick and easy single-sheet specification conversion without cumbersome operations. Sheet adjustment accuracy is as high as 0.005mm

5.The standard machine of the fully automatic sheet winding machine can roll up to 500 kilograms of sheet material with a diameter not exceeding 800mm. Winding machines with larger weight and diameter can also be customized. Our company has also developed an automatic winding machine, which can roll two rolls of sheets at the same time, with high production capacity

Scope Of Application:

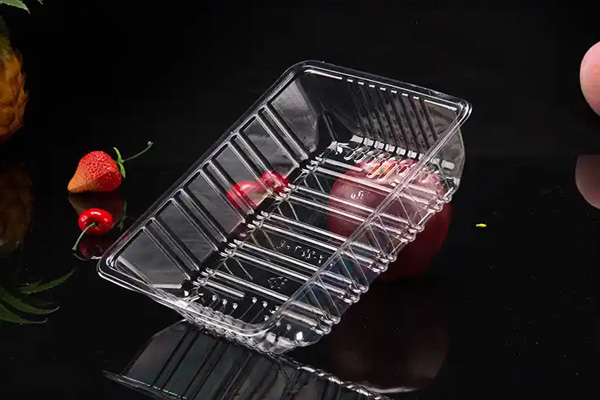

1. PET sheets exhibit high transparency and are non-toxic and odorless, making them environmentally friendly and particularly suitable for easy recycling in food packaging and other applications. PET is currently an ideal thermoforming packaging material, widely used in applications such as vacuum packaging, food packaging, hardware packaging, pharmaceutical packaging, and electronic product packaging.

2. However, during the extrusion process, the hygroscopic nature of PET can compromise product quality. Single-screw extruders offer efficient vacuum venting capabilities, and their planetary venting screw configuration significantly reduces viscosity loss in PET resin, preserving the toughness of the original sheet.

Single Screw PET Sheet Extrusion Machine Lists:

- Mixing-drying Machine

- Ration Feeder

- Masterbatch Mixer

- Extruder Screw

- Hydraulic Filter Changer

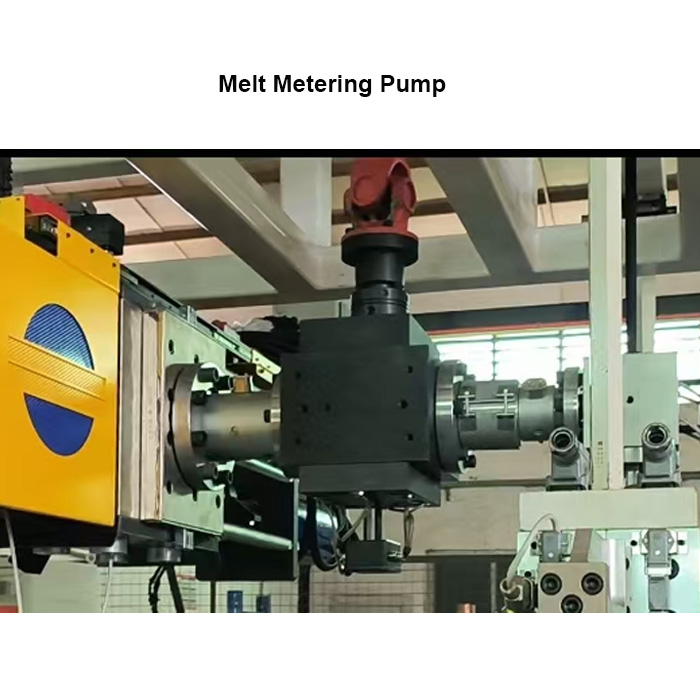

- Metering Pump

- Mould

- Three-roll Calender

- Waste Edge Cutting Device

- On-line Crusher of Waste Edge Material

- Thickness Gauge

- Corona Device

- Oil Coating Device

- Oven

- Traction Machine

- Storage Rack

- Automatic Winder

- Calender Temperature Control System

PET Sheet Extruder Machine Technical Parameters:

| Model/Parameters | Complicable Material | Screw specifications | Sheet thickness (mm) | Sheet width (mm) | Maximum extrusion output (kg/h) | Installed capacity (KW) |

|---|---|---|---|---|---|---|

| TANZ-100PET | PET | Φ100 | 0.2-1.6 | ⩽850 | 200-300 | 210 |

| TANZ-120PET | PET | Φ120 | 0.2-1.6 | ⩽850 | 400-500 | 250 |

| TANZ-130PET | PET | Φ130 | 0.2-1.6 | ⩽850 | 600-700 | 435 |

| TANZ-150PET | PET | Φ150 | 0.2-1.6 | ⩽850 | 800-1000 | 460 |

| TANZ-120/65 | PET/PLA | Φ120/65 | 0.2-1.6 | ⩽850 | 550-650 | 310 |

| TANZ-150/70 | PET/PLA | Φ150/70 | 0.2-1.6 | ⩽800 | 800-1000 | 365 |

Machine Details:

Extruder

It is derived from Taiwan’s technology design, free drying and exhaust type planet type screw,which has the advantages of mandatory feeding,high speed,high production capacity , and high quality . It is suitable for 80% recycling material, maintaining the original toughness of the original sheet.

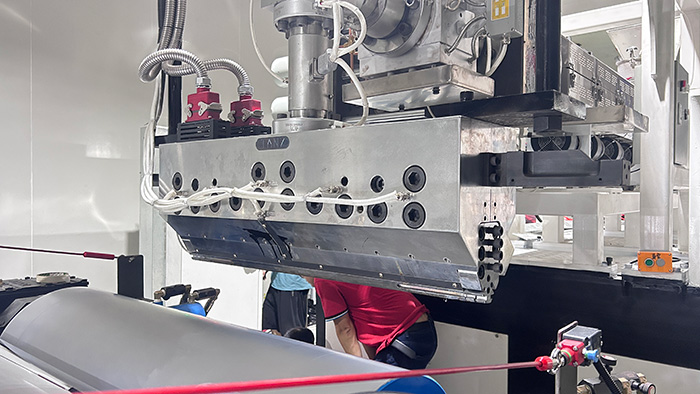

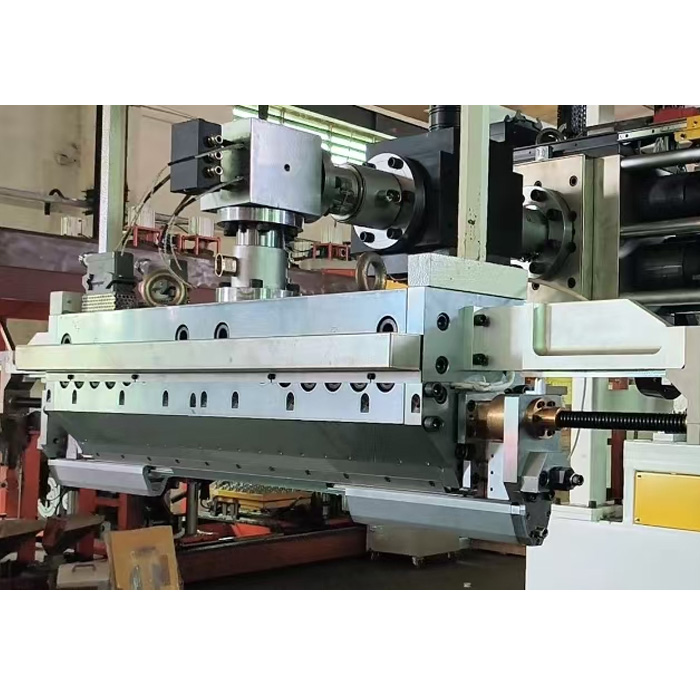

Mould

The mold is made of alloy steel, and the flow channel is chrome-plated and polished, allowing the mold width to be adjusted without stopping the machine.

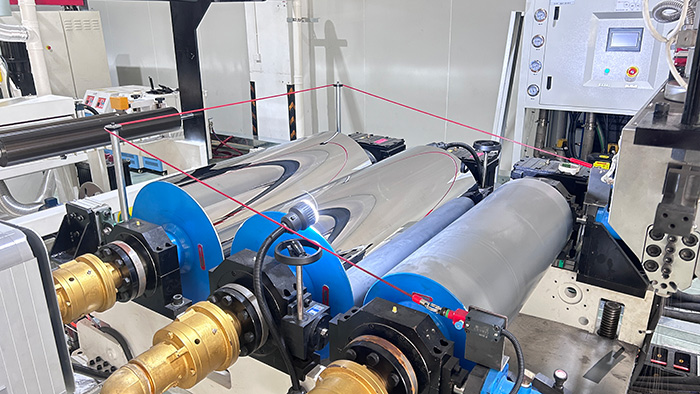

Three-roller calender

The three-roller light machine is a horizontal or vertical or 45 degree inclined design.The thickness of the sheet is automated adjustment system,The machanical roller has anti-collision protection function.The use of electronic hand wheel operations to implement the sheet specifications,which are transformed quickly and relaxed,and no tedious operations are required.The accuracy of slices is as high as 0.005mm.

Two Station Winder

The dual station winding machine is equipped with automatic meter meter , You can also customize a larger volume weight , and the larger diameter can be collected by 1.15 meters . It also specially developed an automatic winding machine that can collect 2 rolls at the same time to achieve high production capacity.