Plastic Sheet Extrusion Line Solutions

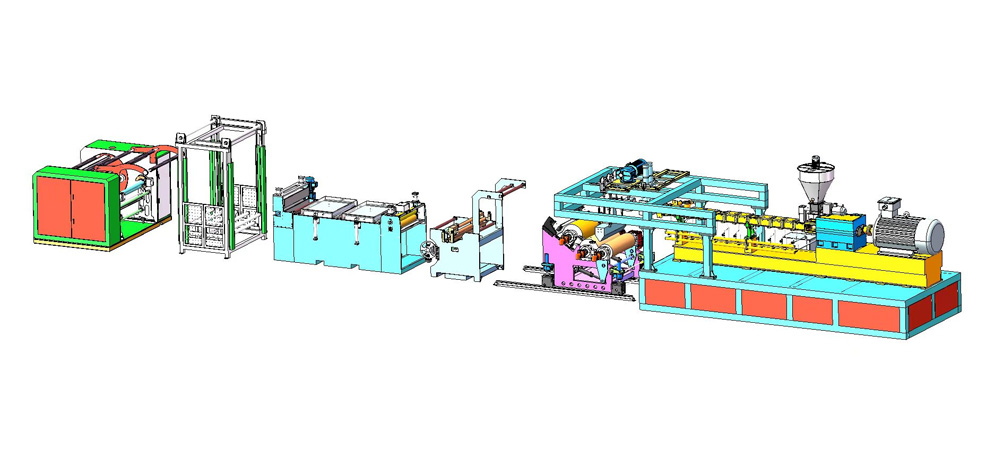

PET sheet extrusion machine, PP/PS sheet extrusion line, PP PS PE multi-layer co-extruded sheet production line, PLA sheet extrusion line. Single Screw, parallel exhaust type twin screws, planetary screws section (do not need crystallizing & drying)

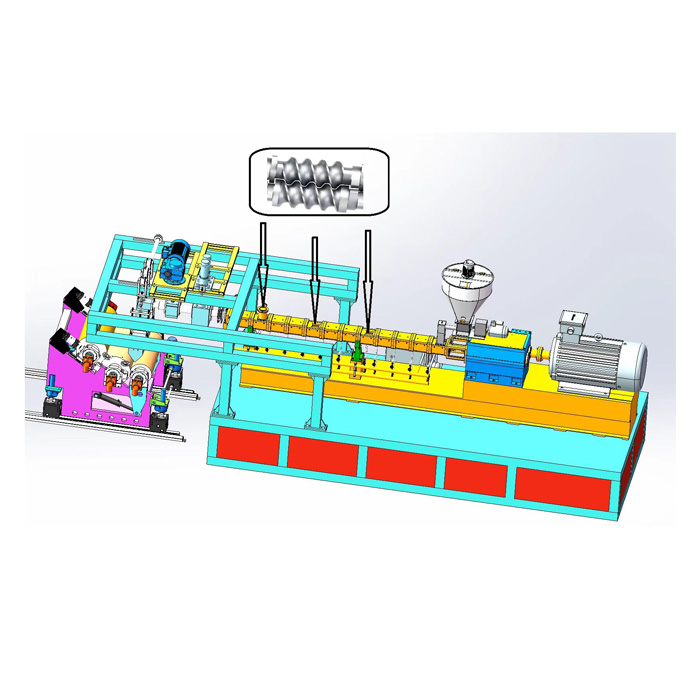

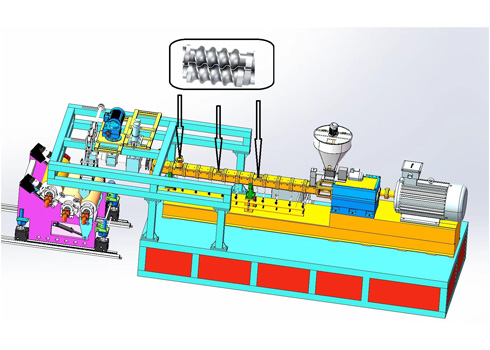

Twin Screw PET Sheet Extrusion Machine_PET Sheet Making Machine

1. Suitable for PET and PLA sheet produciton, do not need crystallizing-drying system, recycling material is ok, high production capacity, low energy consumption, good plasticization performance.

1, Lead Time:1-2 months after deposit confirmed

2, Price Term: FOB,EXW,CFN,CIF,etc.

3,Payments: T/T,Visa,Paypal,etc.

What Is The Functional Feature Of Twin-screw PET Sheet Extrusion Machine?

1, TZ-machinery twin-screw PET sheet extrusion machine is suitable for PET PLA sheet production, do not need crystallizing-drying system, recycling material is acceptable, high production capacity, low energy consumption, good plasticization performance.

2, The screws are building block structure, a multi-combination, and convenient to maintain equiment. The extruder is equipped with two vacuum exhaust to ensure that the water and gas are exhausted fully. The symmetrical thin-walled roller simplifies improve the cooling efficiency, production capacity and sheet quality.

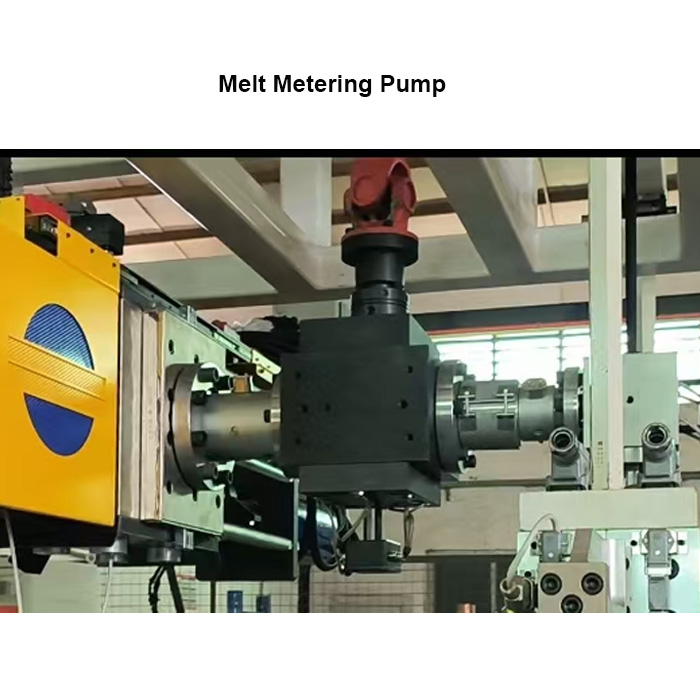

3, the extruder is equipped with metering pump, can control the output stably. Adopt PLC to control the pressure and speed, realize the automation control of parameter setting, data operation and feedback, alarm, etc.

Equipment Parameters:

- Mixing-drying Machine

- Ration Feeder

- Masterbatch Mixer

- Extruder Screw

- Hydraulic Filter Changer

- Metering Pump

- Mould

- Three-roll Calender

- Waste Edge Cutting Device

- On-line Crusher of Waste Edge Material

- Thickness Gauge

- Corona Device

- Oil Coating Device

- Oven

- Traction Machine

- Storage Rack

- Automatic Winder

- Calender Temperature Control System

Technical Parameters:

| Model | Suitable materials | Screw type | Screw specifications | Sheet thickness (mm) | Sheet width (mm) | Maximum extrusion capacity (kg/h) | Installed capacity (kw) |

|---|---|---|---|---|---|---|---|

| TZS-75PET | PET,PLA | cordwood system | Φ75 | 0.12-1.6 | ≦800 | 450-550 | 315 |

| TZS-85PET | PET,PLA | cordwood system | Φ85 | 0.12-1.6 | ≦1000 | 600-800 | 380 |

| TZS-95PET | PET,PLA | cordwood system | Φ92 | 0.12-1.6 | ≦950 | 1000-1200 | 495 |

| TZS-105PET | PET,PLA | cordwood system | Φ100 | 0.12-1.6 | ≦950 | 1200-1500 | 505 |

| TZS85-1200 | Starch-based degradation materials | cordwood system | Φ85 | 0.3-2.0 | ≦800 | 400-500 | 275 |

Twin-screw PET Sheet Extrusion Line Details:

Extruder

Twin screws with exhaust design, can exhaust the water and gas when extruding, do not need crystallizing-drying machines, higher production capacity

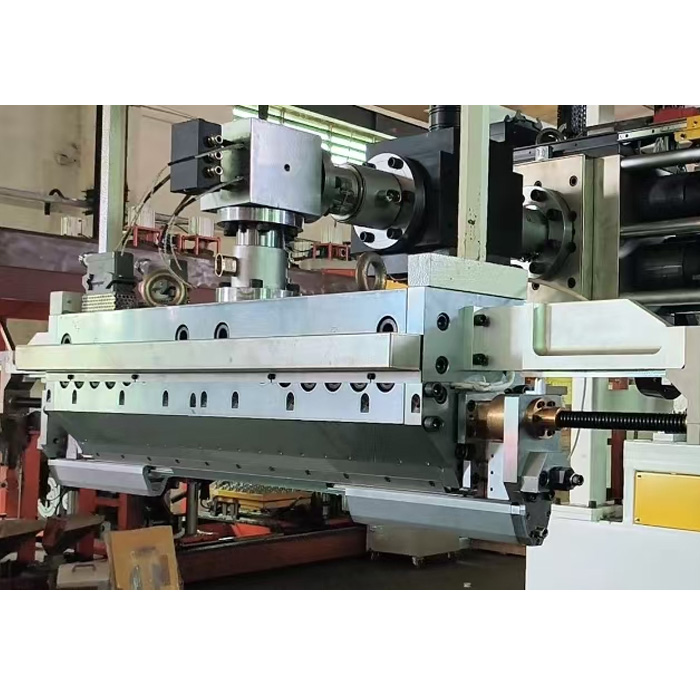

Mould

The mold is made of alloy steel, and the flow channel is chrome-plated and polished, allowing the mold width to be adjusted without stopping the machine.

Three-roller calender

The three-roller light machine is a horizontal or vertical or 45 degree inclined design.The thickness of the sheet is automated adjustment system,The machanical roller has anti-collision protection function.The use of electronic hand wheel operations to implement the sheet specifications,which are transformed quickly and relaxed,and no tedious operations are required.The accuracy of slices is as high as 0.005mm.

Two Station Winder

The dual station winding machine is equipped with automatic meter meter , You can also customize a larger volume weight , and the larger diameter can be collected by 1.15 meters . It also specially developed an automatic winding machine that can collect 2 rolls at the same time to achieve high production capacity.