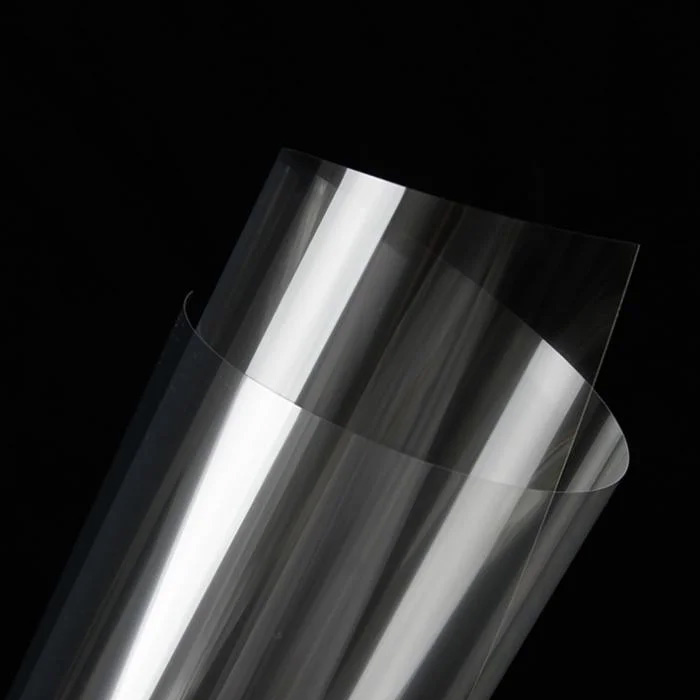

The forming temperature for PET sheets generally ranges from 240°C to 280°C.

This temperature range is suitable for the production process of PET sheets using an extruder, ensuring that PET pellets undergo plastic deformation during the melting process, achieving uniform heating and avoiding quality issues caused by uneven heat distribution.

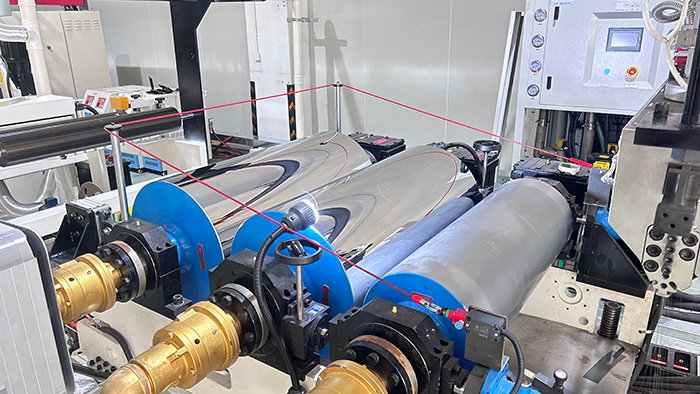

During the extrusion process, both the applied pressure and temperature can significantly influence the quality of PET sheets, such as surface smoothness and tensile properties;

therefore, appropriate adjustments and controls are necessary.

Moreover, the cooling process is also critical, typically requiring the cooling water temperature to be maintained at no higher than 15°C to ensure surface quality and effective cooling of the sheets.