THERMOFORMING MACHINES

Plastic Cup Making Machine

Contact Our Expert

How To Choose The Suitable Thermoforming Machines?

Dear Customers:

Thank your for visiting our thermoforming machine solution page. TZ-machinery has semi-auto thermoforming machine solution, fully automatic integrated thermoforming machine solutions and plastic cup thermoforming machine solution.

It’s very necessary to know the difference of all thermoforming solutions before you make decision to use our machine solution to meet your production requirements.

Below are fast guides for your reading.

Best rgds

TZ-machinery group

SEMI-AUTO

SEMI-AUTOMATIC

INTEGRATED

FULLY-AUTO

INTEGRATED

FULLY-AUTO

INTEGRATED

FULLY-AUTO

Plastic Cup Machine

Plastic Cup Machine

Plastic Cup Machine

Plastic Cup Machine

Advantages Of Integrated Fully-auto Thermoforming Machines:

Quick Mold Change

Quick Mold Change

Point To Point

Heating Temperature Control

Mold Cost Budget For Reference Of Integrated Thermoforming Machine:

Plaster Mold

USD70 ~ USD120/set, based on the exact product design. For sample making.

Copper Mold

USD1300 ~ USD1600/set, based on the exact product design. For small customized order.

Aluminum Mold

USD5000 ~ USD7200/set, based on the exact product design. For big quantity order.

Last But Very Important For Your Decision Making:

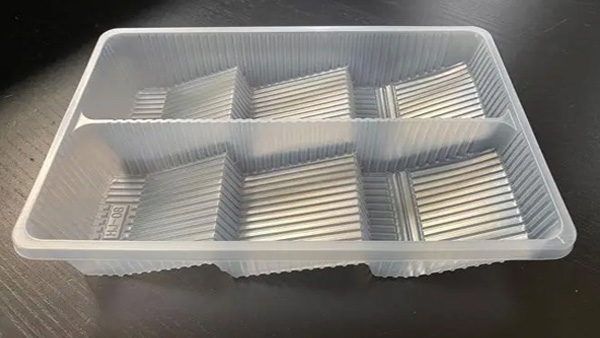

1, Determine The Specification And Shape Of Ther Thermoforming Products:

Different thermoforming products require thermoforming machines of different specifications and shapes to produce. Therefore, when choosing a thermoforming machine, you need to first clarify the specifications and shapes of the thermoforming products you need to produce.

2, Determine The Output And Production Time:

When choosing a thermoforming machine, you need to determine the number of 2,thermoforming products you need to produce and the production time, so as to determine the production capacity and production efficiency of the thermoforming machine, and thus choose a thermoforming machine that suits you.

3, Forming accuracy: The forming accuracy of the thermoforming thermoforming machine has an important impact on product quality, so the forming accuracy of the equipment needs to be considered.

Thermoforming thermoforming machines are divided into two types: semi-automatic and fully automatic.

The models are further divided into high-speed servo forming machines (semi-automatic), Fully automatic three/four-station negative pressure thermoforming forming all-in-one machine, and fully automatic three/four-station positive & negative pressure thermoforming forming all-in-one machine

High-speed servo forming machine (semi-automatic): Suitable for products with larger sizes and more product types. Its advantage is that the forming mold can choose gypsum mold, copper mold, aluminum mold, which is flexible for product production (TZ-1220F).

Fully automatic three/four-station negative pressure thermoforming molding machine: molding-punching-punching-stacking, fully automatic integrated production, low energy consumption, labor saving, molding molds can choose plaster molds, copper molds, aluminum molds, to meet the production needs of most customers (TZ-7695)

Fully automatic three/four-station negative pressure thermoforming molding machine: molding-punching-punching-stacking, fully automatic integrated production, low energy consumption, labor saving, high output, molded products with strong three-dimensional sense, uniform thickness, molding molds can only be aluminum molds, suitable for large-scale order production, customers with high requirements for product quality and output (TZ-7385, TZ-7265).

For more details, pls send us your inquiry from the left form. Or whatsapp to our expert, we will response to you as soon as possible.