Thermoforming Machines

Proven technologies, complete solution, rich experience, fully-automatic, semi-automatic, three/four stations; Produce food container, fruit packaging boxes, egg trays, seedling trays, electronic trays, food trays, clamshell, etc.

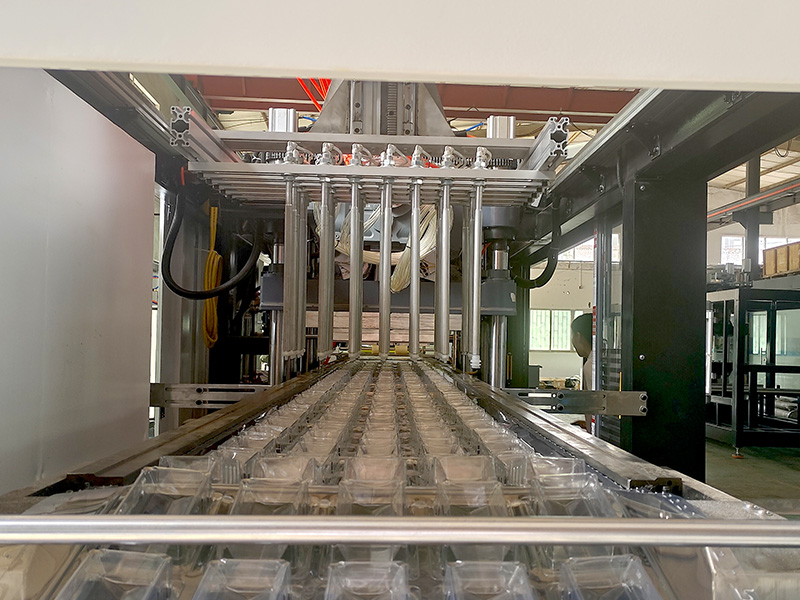

TZ-7385 Fully Automatic Positive And Negative Pressure Thermoforming Machines ( Three/four Stations )

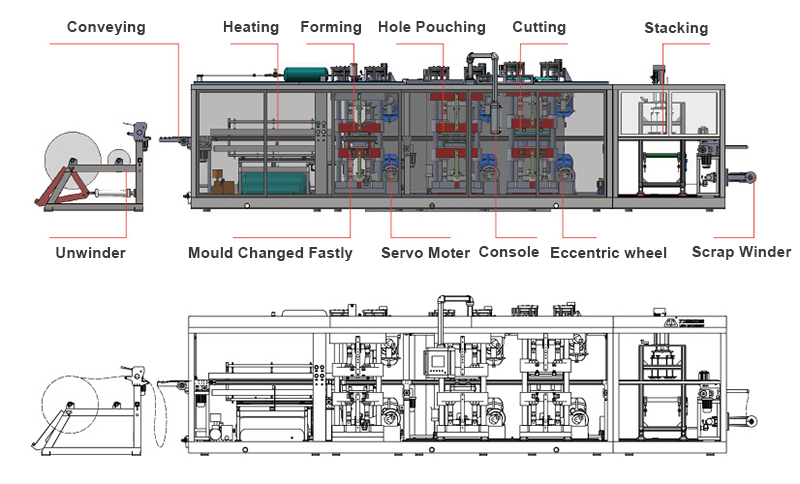

TZ-7385 thermoforming machine, forming size:730x850mm, fully automatic thermoforming machines, driven by servo completely, three/four station thermoforming machine: forming, cutting(hole pouching, cutting), stacking; Suitable for producing electronic trays, food containers, vegetable and fruit packaging boxes, finished tool trays, seeding tray, egg tray, etc.

1, Lead Time:1-2 months after deposit confirmed

2, Price Term: FOB,EXW,CFN,CIF,etc.

3,Payments: T/T,Visa,Paypal,etc.

TZ-7385 Thermoforming Machine Features:

Aopts plastic sheet thermoforming technology, it is an integrated of machines, electricity, and gas. PLC control system, Human machine inferface. Both concase and convex molds can be formed’ Three stations: forming, cutting, stacking; four stations: forming, hole pouching , cutting,stacking. Fully automatic, can produce product automatically. Need less labor, convenient to operate, improve production efficiency. The workshop is clean, high degree of automation. It’s a flow-type production line which is specialized in thermoforming and pouching products.

Scope Of Application:

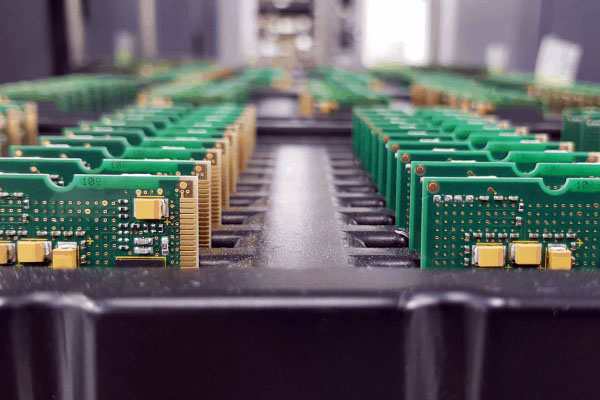

Suitable for forming of 0.15-2.0 mm thermoplastic materials, such as PS HIPS PET, PP, KPS, GPET, PLA, and so on. Can produce high transparent, high stretching, round, square, irregular, up and down stretching and flanging products. Such as plastic food box, electronic trays, food packaging boxes, medical packaging boxes, finished tool packaging, seedling trays, disposable bowls, plates, and other plastic products.

Food Packaging Box

Fruit Packaging Box

Clamshell

Egg trays

Electronic Trays

Seedling Trays

Meat Packaging Box

Food Trays

Technical Parameters Of TZ-7385 Thermoforming Machine:

| No. | Model | TZ-7385 (Big Forming Area) |

| 1 | Forming Method | Positive and negative pressure forming |

| 2 | Forming Area | Formed Sheet Length: 440-870mm,formed sheet width: 410-790mm |

| 3 | Forming Depth (Max.) | 110mm |

| 4 | Sheet Thickness | PS:0.16-2.0mm PP:0.16-1.6mm PET/PVC:0.16-1.2mm |

| 5 | Suitable Materials | PP,PS,PET,PVC,BOPS,PLA,etc. |

| 6 | Cutting thickness | 0.16-2.0mm(hot die cutting if more than 1mm ) |

| 7 | Total Power | Installed capacity 140KW (maximum power) |

| 8 | Forming Speed | 40times/min |

| 9 | Upper Mold Forming Station | 5.5kw Inovance Servo Drive |

| 10 | Lower Mold Forming Station | 5.5kw Inovance Servo Drive |

| 11 | Upper Punching Station | 7.5kw Inovance Servo Drive |

| 12 | Lower Punching Statioin | 5.5kw Inovance Servo Drive |

| 13 | Strech | 3.0kw Inovance Servo Drive |

| 14 | Stacking | 2.0kw Inovance Servo Drive * 2 |

| 15 | Touch Screen | German Siemens 12.5 inch color touch screen |

| 16 | Solenoid Valve,water and oil barrier | Japan “CKD” |

| 17 | Heating Brick | Upper furnace:120pcs 650w heating brick;lower furnace:60pcs 650w heating brick;heating area length: 2080mm (three-section heating areas) |

| 18 | Equipment main electrical conpoments:German Siemens, Japam Fuji | |

| 19 | Cooling method: One water chiller, 5HP (compressor “Panasonic” or “Copeland”) | |

| 20 | Negative pressure generation method: one 160㎡ vacuum pump. | |

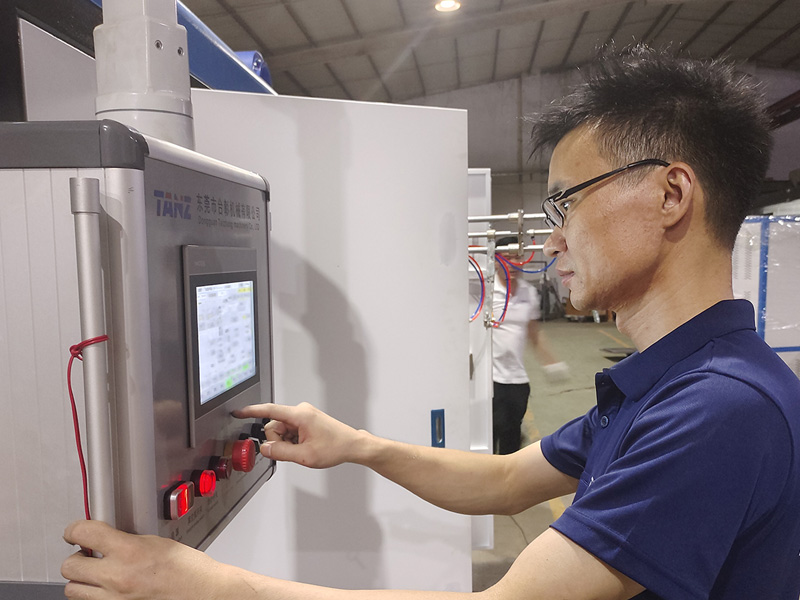

| 21 | Adopt PLC programmable control and human-machine interface German Siemens 12.5-inch color touch screen operating system, this system can greatly enhance the stability and response speed of each action process | |

| 22 | Adopt 4.5kw servo motor to convey,accurate,stable and easy to operate | |

| 23 | have 1000 memory units,can store production dates,convenient to find the old dates to produce. | |

| 24 | Silicone oil spraying system for feeding | |

| 25 | Partial cylinders: Yadeke, Yongyi | |

| 26 | Air switch, contactor, travel switch: Japan “Fuji” Relay: France “Schneider” | |

| 27 | Main frame: Steel plate, angle iron, pig iron, stainless steel,made in China | |

| 28 | Rail: aluminum mold-extruded rail,surface oxidation treatment | |

| 29 | Stacking method: take the product from mold and stab the product. | |

| 30 | Production line: Fully automatic productin line | |

| 31 | Weight which the winder can bear:500kgs | |

| 32 | Max.Machine Power:140Kw, actual consumption power:50-60Kw,Power Supply:AC 380V,50Hz, Three-phase, Four-wire ; One-to-one temperature system, save more energy | |

| 33 | Equipment size: L: about 12.3 m,W: 2.15 m, H: 2.8 m, Weight: about 11 tons | |

Production Process:

TZ-7385 Thermoforming Machine Details:

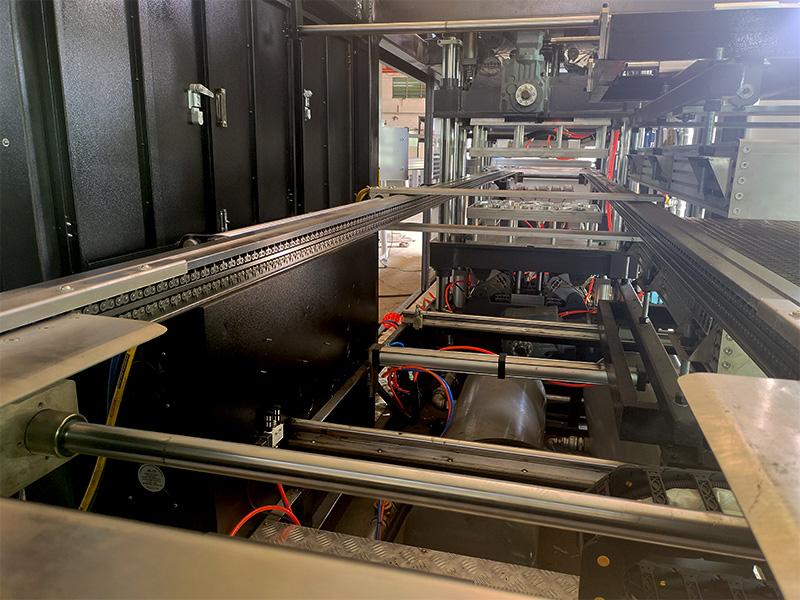

The feeding system uses a motorized lift capable of supporting 500 kg. The material is delivered using rubber rollers, with two material rods for sheet replacement.

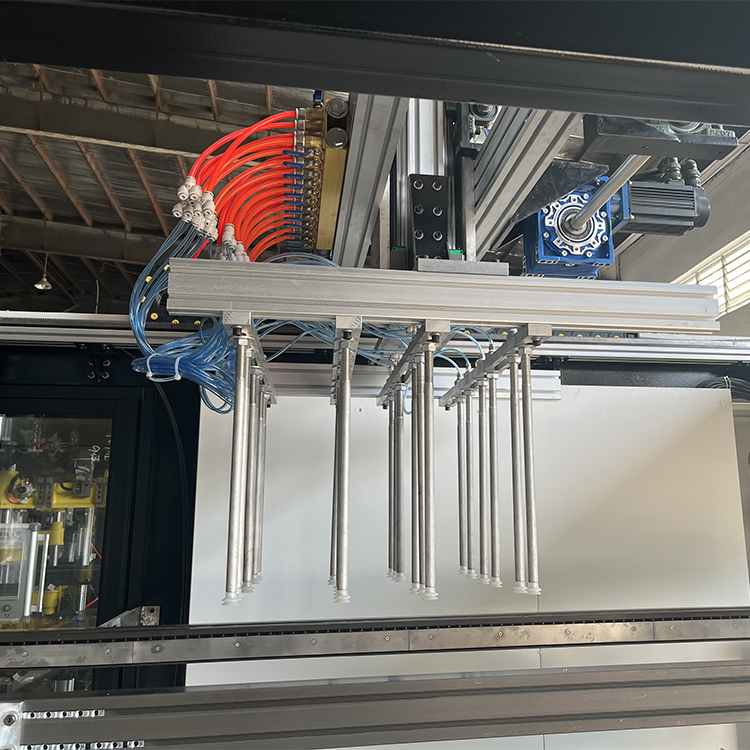

The plastic sheet was sent by the sharp tooth, which was driven by the servo-motor. The width of the chain can be adjusted. Aluminum extruded chain truck, silicon steel.

Furnace temperature system adops PLC which can control the ceramic heating parts one to one. convenient to adjust the temperature, easy to operate, quick to heat up, low energy consumption.

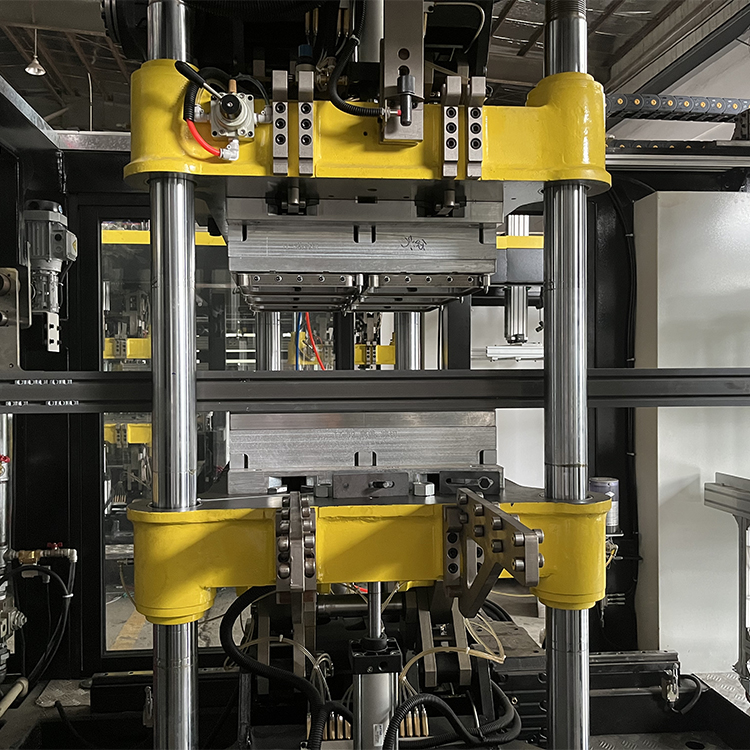

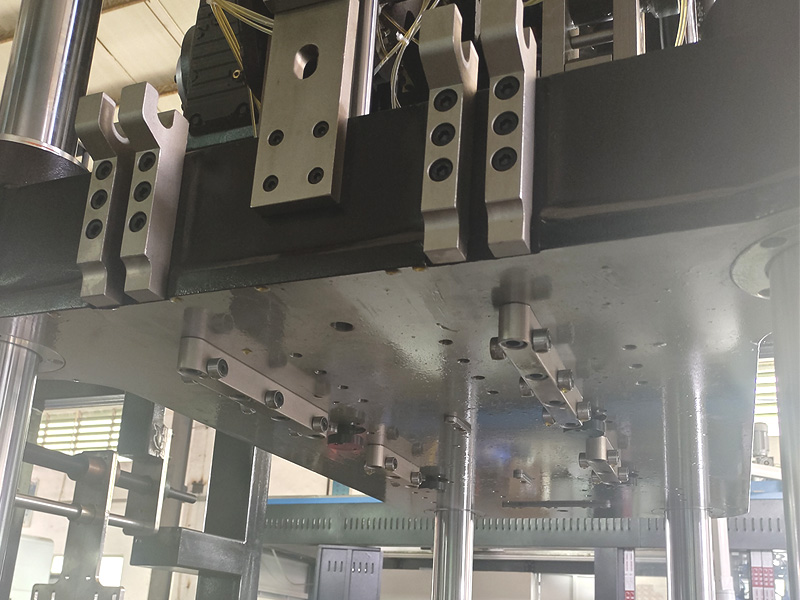

The installation of the mold is easy and safe, it can short the setting time of the mold. Using the mold change bracket can improve the efficiency of changing mold.

Siemens 10.1 color touch screen, LC integrated module design. Have button operations, can set and modify the process parameters. Easy and convenient to operate and maintain.

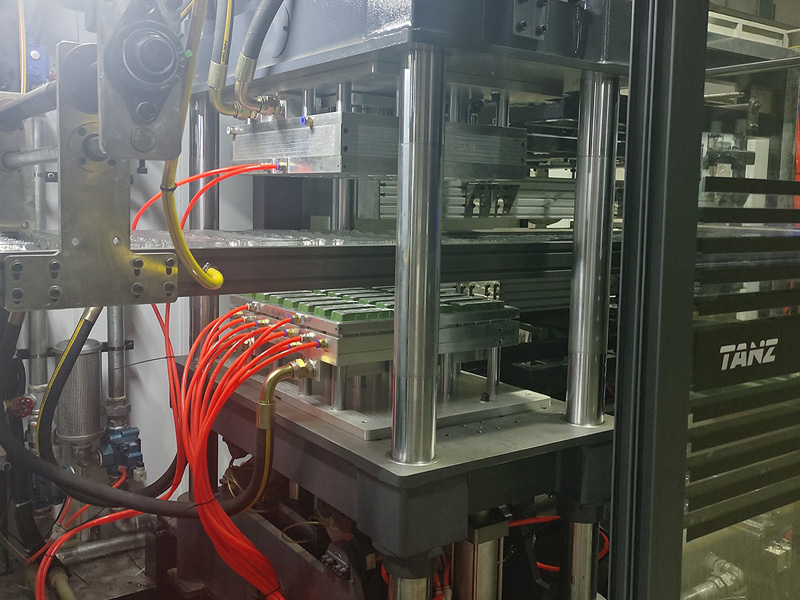

Driven by servo motor to close the mold, with cylinder clamping frame and servo stretching function at the same time.

Has an automatic mold locking system, which can fix the mold after the installation and adjustment. Don’t need screws to fix the mold and can short the setting time of the mold. It can improve efficiency. And the cutter has heat functions.

Stacking station has multi-functional stacking modes, normally choose automatic up and down stacking manipulator and manipulator (take products from cutting mold out and then stack on the conveyor belt).