Thermoforming Machines

Proven technologies, complete solution, rich experience, fully-automatic, semi-automatic, three/four stations; Produce food container, fruit packaging boxes, egg trays, seedling trays, electronic trays, food trays, clamshell, etc.

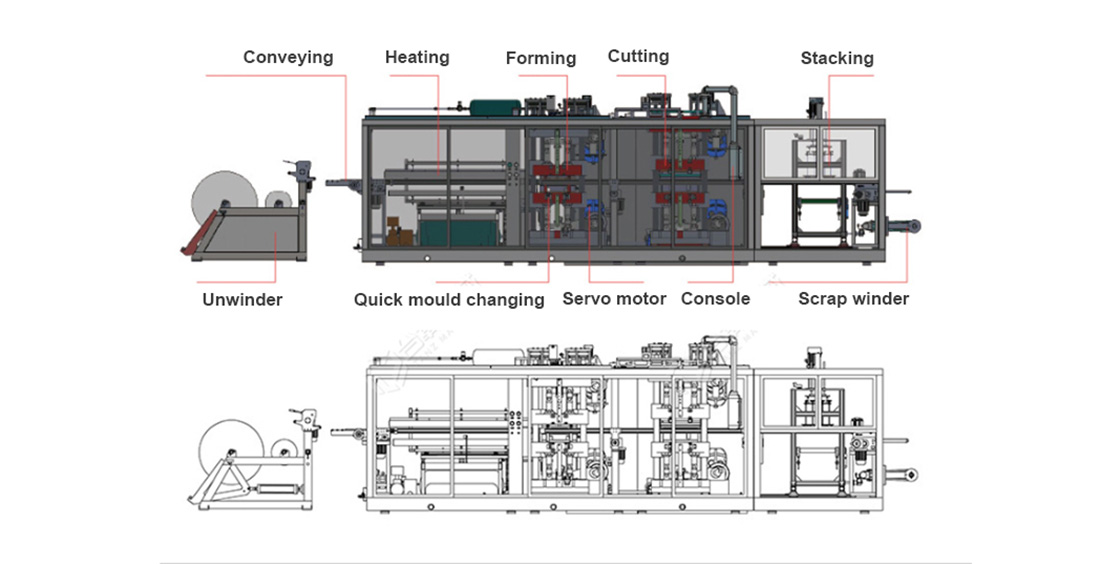

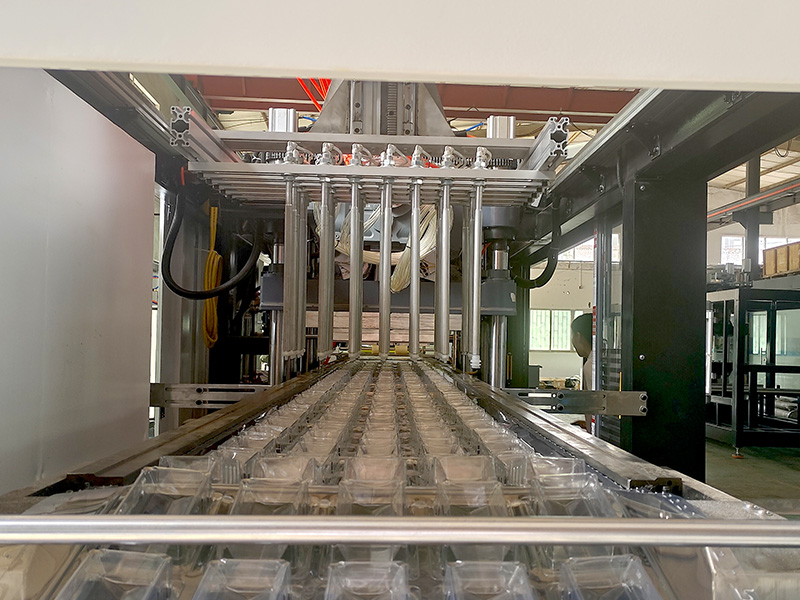

TZ-7695 Fully Automatic Negative Pressure Thermoforming Machines ( Three/four Stations )

Forming Area: 760 x 950mm, Servo drive completely, no noise, no vibration, easy to thermoforming, fast speed; three/four stations : forming, cutting (hole pouching, cutting), stacking Suitable for producing disposable food container, fruit packaging boxes, egg trays, seedling trays, clamshell, etc.

1, Lead Time:1-2 months after deposit confirmed

2, Price Term: FOB,EXW,CFN,CIF,etc.

3,Payments: T/T,Visa,Paypal,etc.

TZ-7695 Thermoforming Machine Features:

1, completely driven by servo, no noise, no vibration, good thermal forming, fast speed.

2,The automatic discharge device of the furnace can be lowered at any time during the production process, without breaking the plate and wasting materials.

3,The electric furnace temperature control system adopts intelligent automatic compensation control and a one-time control regulator, which is easy to adjust the temperature evenly, is easy to use, easy to operate, and heats up quickly. It can bake low-temperature slices up and down three times in the oven.

4,Forming and slitting mold servo drive, with bi-directional adjustable upper and lower mold travel, and electrically adjustable upper mold closing direction. In the closed mode, the height and position of the upper and lower molds can be easily and quickly adjusted; The direction of the lower mold closing is easy to approach and buffer, improving the closing speed and avoiding vibration.

5,PLC automatic cutting, automatic counting, and automatic transmission.

6.Effortless, only 1-2 workers need to pack.

Scope Of Application:

1,It is suitable for forming thermoplastic materials with a thickness of 0.15-2.0mm, such as PS HIPS, PVC, PET, PP, PE, PS, KPS, GPET, ABS, etc., and can process high transparency, high tensile, round, square, irregular, up and down two-way tensile, and flanging products.

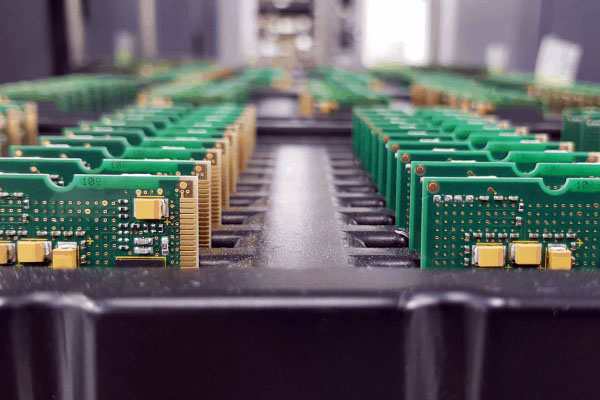

2. Electronics: turnover pallets for semi-finished electronic product production lines, cost packaging for electronic products, etc.

3. Food category: frozen food packaging trays, ice cream lids, ice cream boxes, food packaging trays, fast food boxes, plates, coffee beverage cup lids, cooked food packaging boxes, etc.

4. Fruits and vegetables: fresh food packaging trays, fruit packaging boxes, etc.

5. Pharmaceutical products: Injection trays, solid drug trays, bottle trays, etc.

6. Electrical appliances: refrigerator lining, electrical vacuum molding accessories, small electrical appliance packaging, etc.

6. Tool category: tool finished product packaging, etc.

7. Alcohol: Fixed trays for bottle packaging, etc.

8. Agriculture: Flower pots, seedling trays, etc.

Food Packaging Box

Fruit Packaging Box

Clamshell

Egg trays

Electronic Trays

Seedling Trays

Meat Packaging Box

Food Trays

Technical Parameters Of TZ-7695 Thermoforming Machines:

| Model | TZ-7695 |

|---|---|

| Forming Method | Negative Pressrue Forming |

| Mould Size (Max.) | 760*950mm |

| Forming Depth (Max.) | Forming Height≦120mm; Forming Depth≦110mm ; forming depth can be up to 150mm if custom. |

| Sheet thickness: | 0.16-2.0mm |

| Forming Speed (Max.) | 20times/min |

| Air pressure | 0.6-0.8mpa |

| Sheet width (Max.) | 430-790mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Heating Power | 90KW |

| Rated power | 120Kw |

| Procedure | Forming-punching-cutting-stacking |

| Dimension | L105000*W2150*H2800mm |

| Weight | About 11T |

Main Electrical Components:

| MODEL/PARTS | TZ-7695 |

|---|---|

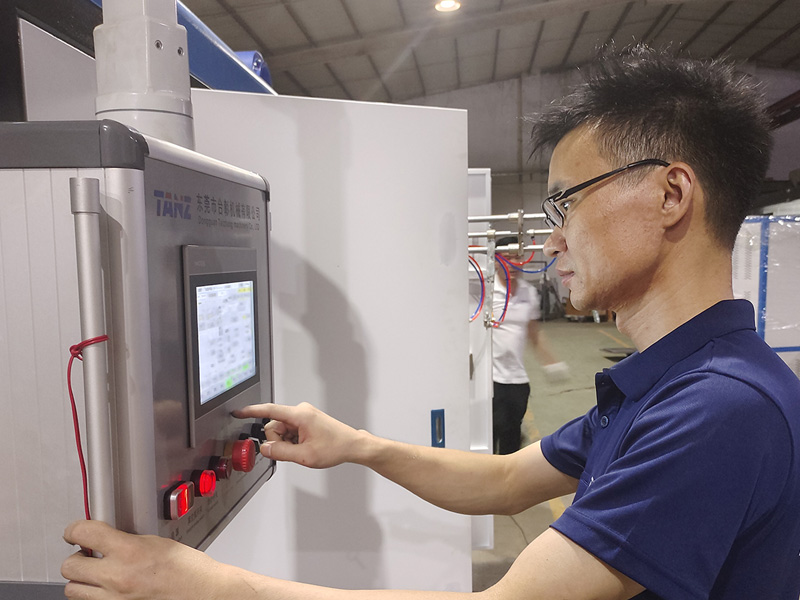

| Touch Screen | KUNLUN TONGTAI(CHINA) |

| PLC | Siemens |

| Servo pack | Inovance |

| Servo Motor | Inovance |

| Heater | ELSTEIN(Germany) |

| Temperature control module | Yamatake Temperature Control system (Japan) |

| Filter | CKD(Japan) |

| Solenoid Valve | CKD(Japan) |

| Solid State Relay | OMRON(Japan) |

| Proximity Switch | OMRON(Japan) |

| Circuit Breaker | SCHNEIDER(France) |

| AC Contactor | SCHNEIDER(France) |

| Power switch | Fuji (Japan) |

Production Process:

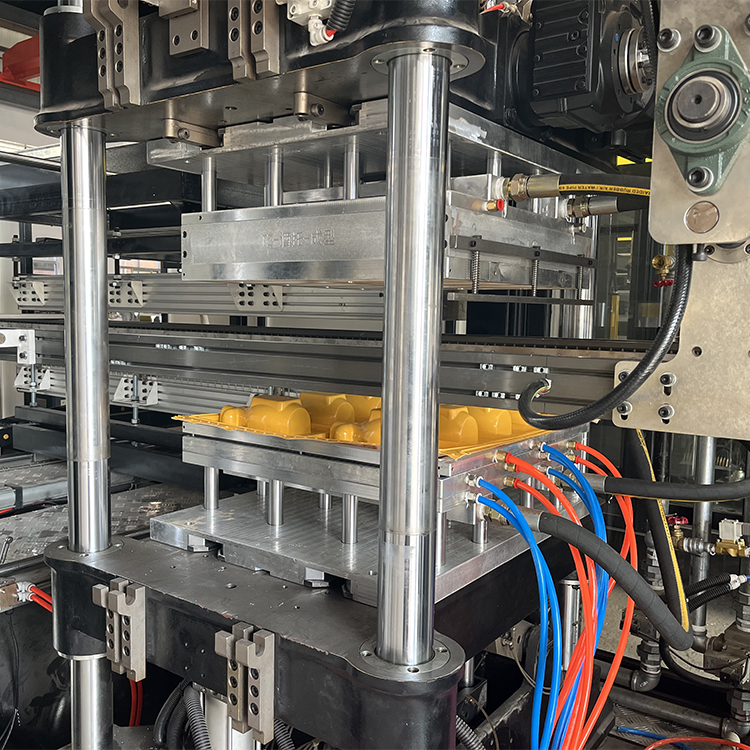

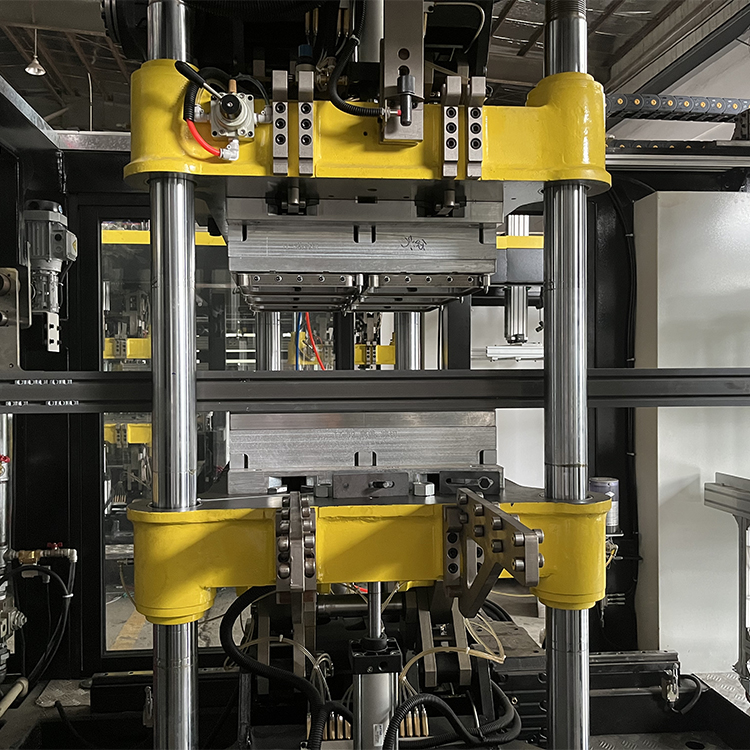

TZ-7695 Thermoforming Machine Details:

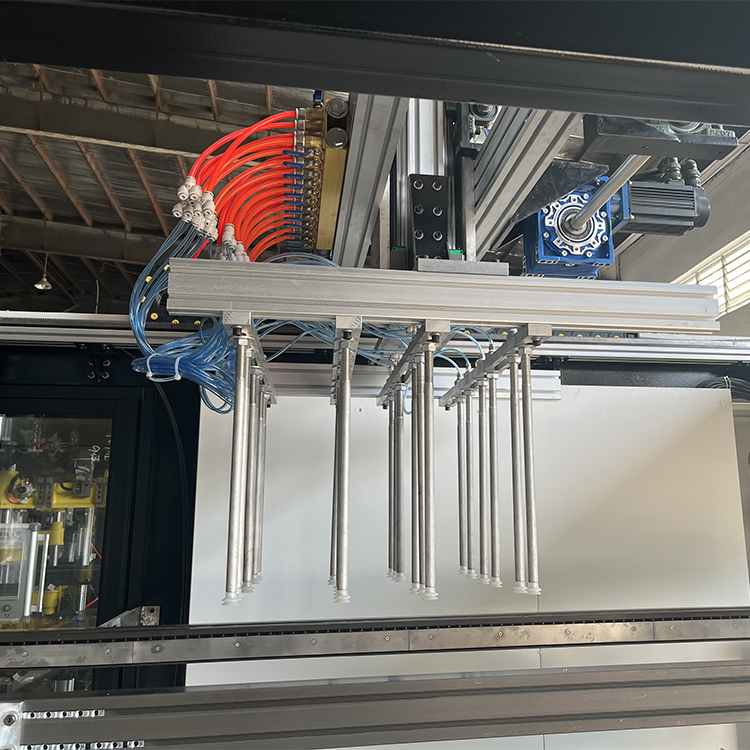

The feeding system uses a motorized lift capable of supporting 500 kg. The material is delivered using rubber rollers, with two material rods for sheet replacement.

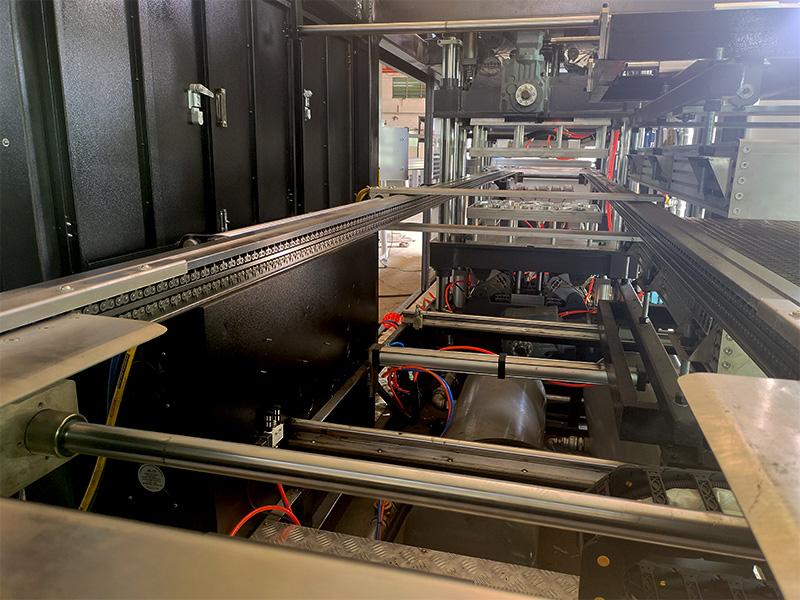

The plastic sheet was sent by the sharp tooth, which was driven by the servo-motor. The width of the chain can be adjusted. Aluminum extruded chain truck, silicon steel.

Furnace temperature system adops PLC which can control the ceramic heating parts one to one. convenient to adjust the temperature, easy to operate, quick to heat up, low energy consumption.

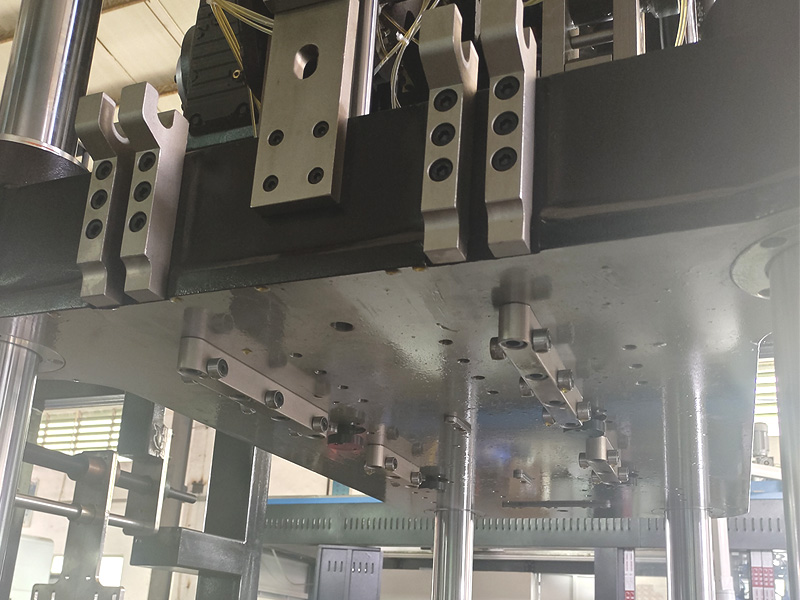

The installation of the mold is easy and safe, it can short the setting time of the mold. Using the mold change bracket can improve the efficiency of changing mold.

Siemens 10.1 color touch screen, LC integrated module design. Have button operations, can set and modify the process parameters. Easy and convenient to operate and maintain.

Driven by servo motor to close the mold, with cylinder clamping frame and servo stretching function at the same time. Spray gun cool product and make it form fast.

Has an automatic mold locking system, which can fix the mold after the installation and adjustment. Don’t need screws to fix the mold and can short the setting time of the mold. It can improve efficiency. And the cutter has heat functions.

Stacking station has multi-functional stacking modes, normally choose automatic up and down stacking manipulator and manipulator (take products from cutting mold out and then stack on the conveyor belt).