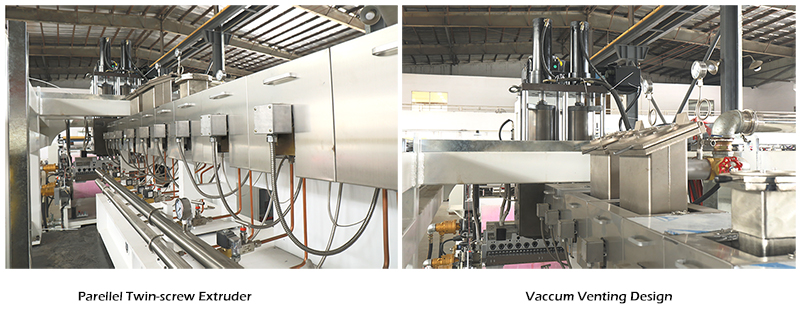

Discover the advantages of parallel twin-screw PET sheet production line with vacuum venting systems: enhanced devolatilization, energy efficiency, high-output production, and superior PET sheet quality.

Enhanced Mixing & Plasticization:

Twin-Screw Synergy: Intermeshing parallel screws deliver high shear force & dispersion mixing, ideal for high-viscosity, crystalline PET materials.

Precision Thermal Control: Shortened melt residence time minimizes thermal degradation risks.

Vacuum Devolatilization Benefits:

Moisture & VOC Removal: Efficiently extracts moisture (<0.005% target) and volatile compounds (e.g., acetaldehyde) to prevent hydrolysis.

Defect Reduction: Eliminates bubbles, fish-eyes, and impurities for higher clarity PET sheets.

High Productivity & Stability:

24/7 Continuous Operation: Stable output for industrial-scale PET sheet production.

RPET Compatibility: Handles recycled PET or fiber-filled formulations with vacuum-assisted impurity removal.

Energy Efficiency & Sustainability:

Lower Energy Consumption: Reduced pre-drying needs + optimized screw design cut operational costs.

Eco-Friendly Compliance: VOC emissions centralized treatment meets environmental standards.

Superior PET Sheet Performance:

Mechanical Strength: Uniform melt flow enhances tensile strength and impact resistance.

Optical Clarity: Bubble-free sheets meet food-grade packaging transparency requirements.