A business partner told us that their customer need a PET sheet extrusion line for their 3 fully-auto multi-station integrated thermoforming machines (we supplied to them). Their customer manufactures PET fruit container, PET food trays, and other PET sheet thermoforming trays. And they want a PET sheet production line with 450-500kg/h extrusion volume.

Our TZS-75 parallel twin-screw PET sheet extrusion machine output is 450-550kg/h, and installed power is 315kw/h (actual power will be low to 70%).

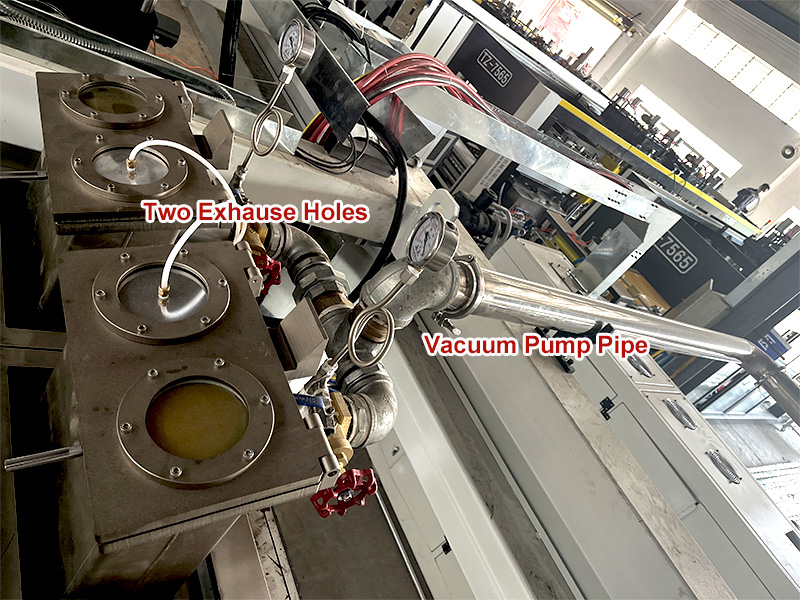

Parallel Twin Screw + Vacuum Exhaust System:

When the PET melt is conveyed to the two exhaust holes by the rotation and shear of the 75 parallel twin screws. The vacuum pump will suck the moisture and gas from hole cavities. Therefore, our PET sheet extrusion line do not need extra crystallizing tower and drying tower to pretreat the PET raw materials. At the same time, this screws + vacuum pump design can guarantee the quality of the PET extruded sheet.