1, Single screw PET sheet extrusion line: APET, PETG, CPET sheet extrusion production line is a mature and stable solution, most PET sheet extrusion machine adopt one extruder extrusion or two extruder co-extrusion. Taiz uses new technology, can improve 30% comprehensive effectiveness.

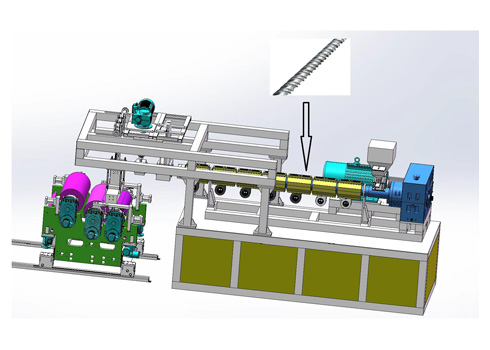

2,Exhaust type single screw PET sheet extrusion line: just need crystalizing PET material, do not need drying. Advantage: low energy-consumption, simple process, easy to maintain equipment.

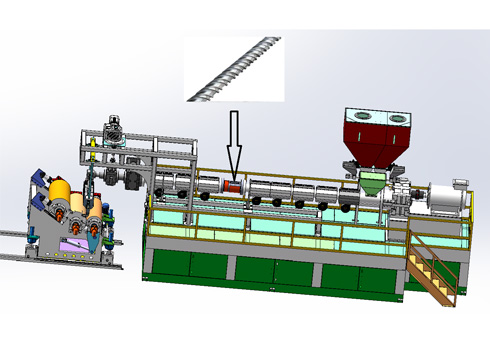

3, Exhaust tyupe Parallel twin-screw PET sheet extrusion line: do not need crystallizing tower and drying tower to pretreat PET material. lower energy-consumption, higher comprehensive effectiveness.

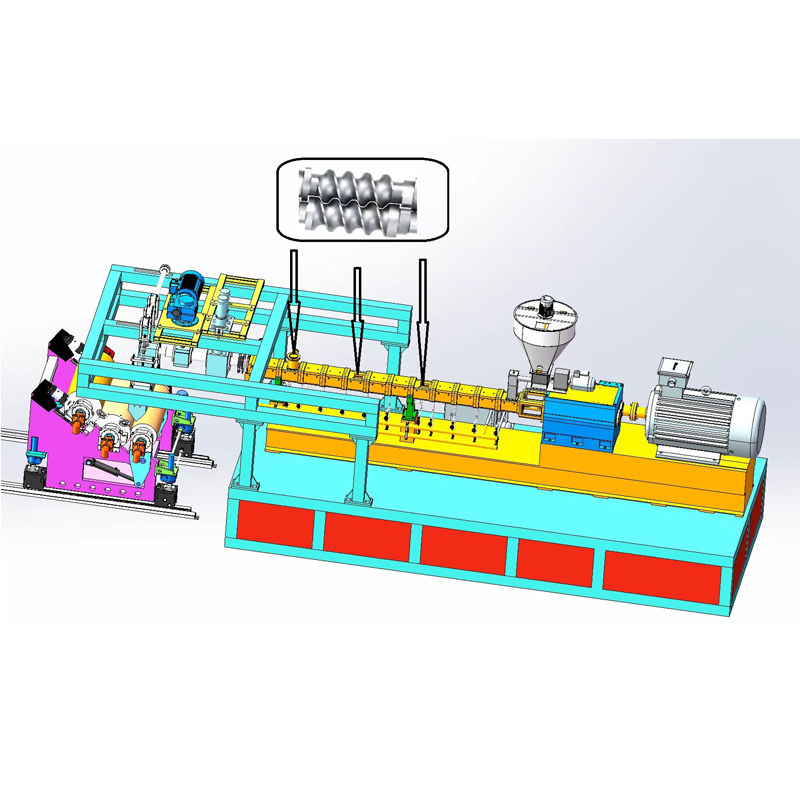

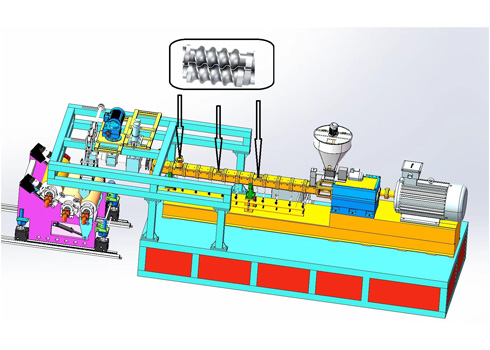

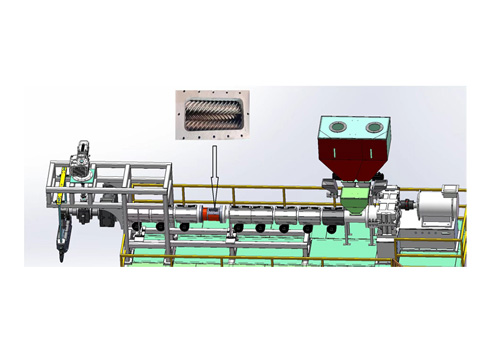

4, Single screw PET sheet extrusion line with planetary-screw section design: do not need crystallizing tower and drying tower. adopt planetary screw technology extuder, it will increase area of the PET melt and air while rotating the small planetary screws. Taiz researched and developed vavuum pump system can suck and vent out the water and gas in the planetary screw section. The PET sheet extrusion line can meet customers’ requirements of big production capacity and high-quality sheet

PET Sheet Extrusion Machine Types:

| Machine Type | Single screw PET sheet extrusion line | Exhaust type single screw PET sheet extrusion line | Exhaust tyupe Parallel twin-screw PET sheet extrusion line | Planetary Screws PET sheet extrusion line |

| Raw Material Treatment | Crystallizaing & drying | Crystallizing | do not need crystallizing & drying | do not need crystallizing & drying |

| Sheet Structure | Single layer extruded sheet, double-layer co-extruded sheet, multi-layer co-extruded sheet | |||

| Sheet Width | ⩽850mm | |||

| Sheet Thickness | 0.2~1.6mm | |||

| Production Capacity | 200kg/h~1000kg/h | |||