What is sheet extrusion? (how do the plastic sheet extrude?)

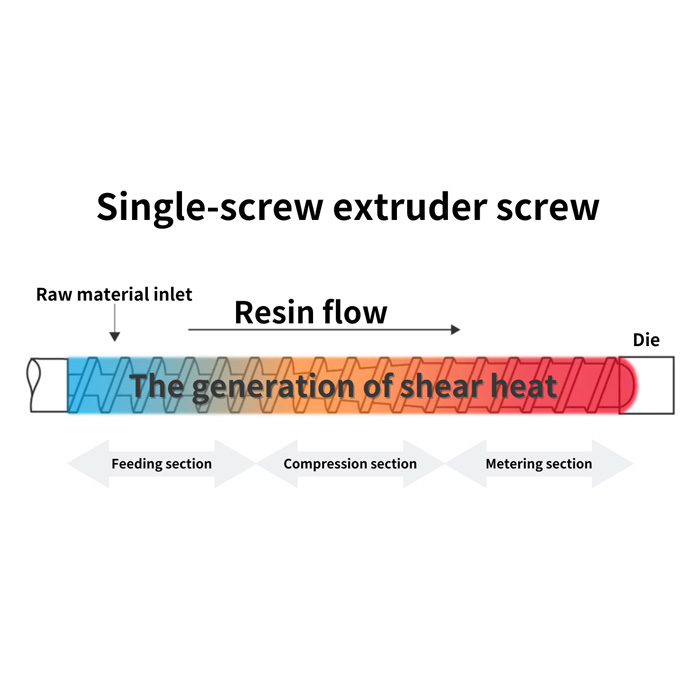

Plastic pellets (which may contain additives) are conveyed from the hopper of the extruder into a heated barrel through a rotating screw by pressure and shear. Within this barrel, the pellets are melted and homogenized before being conveyed to the sheet die.

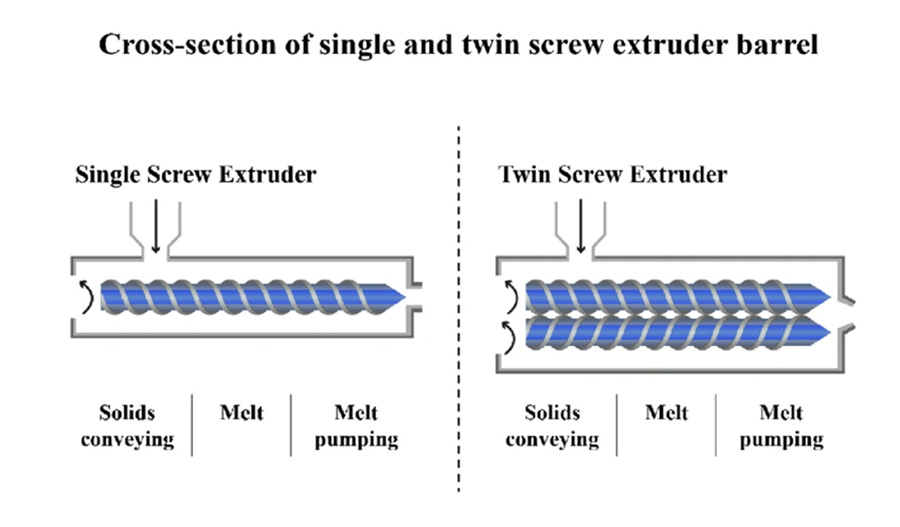

Depending on the specific application, a variety of configurations can be employed, including variations in the number and rotation of screws, as well as the geometric design and structure of both the screw and the barrel. The die itself can facilitate the co-extrusion of different thermoplastic materials (such as recycled plastics) from multiple extruders, enabling the production of layered or concentric materials.

Subsequently, the extrudate is cooled using three-roll calender and transported to slitting and winding stations. Additionally, thermoforming processes can be executed inline to sheet extrusion production line as required.