A. The difference between twin screw and single screw In industrial production, the screw is a commonly used transmission element used to convert rotational motion into linear motion or torque into force. Twin screws and single screws are the two common forms of screws. The main differences between them lie in the following aspects:

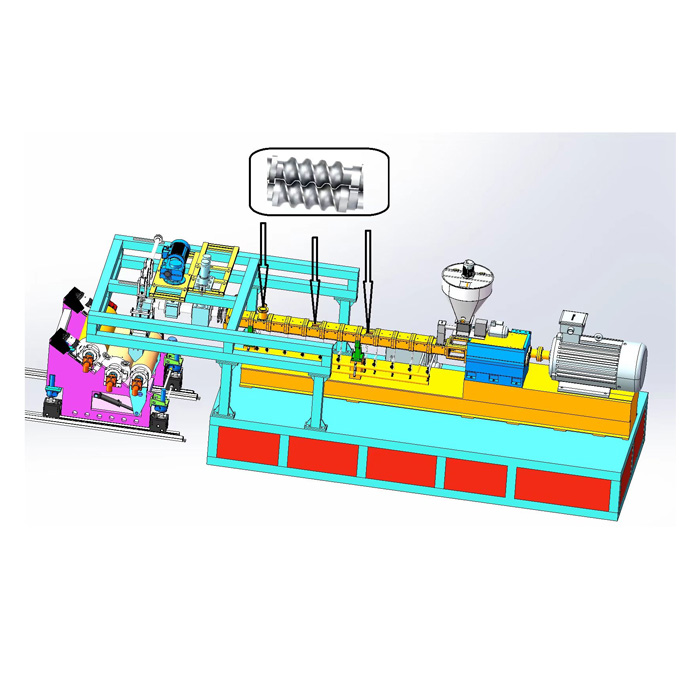

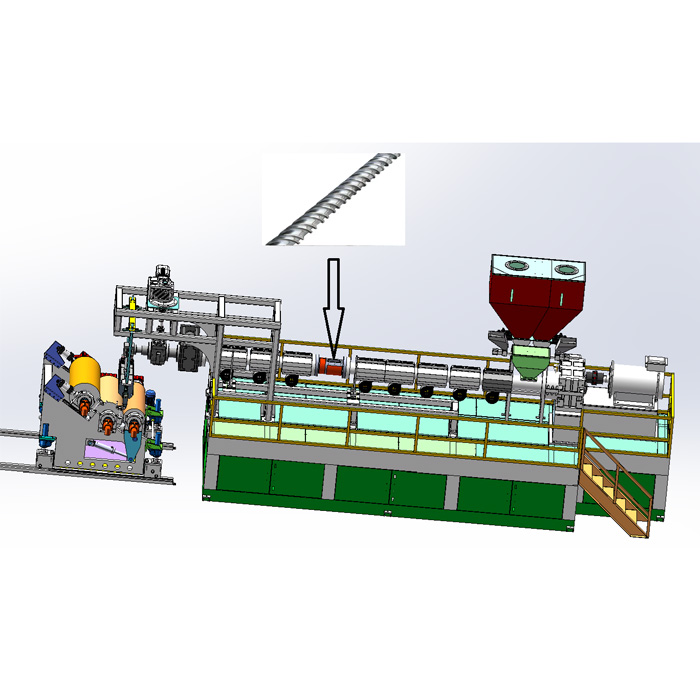

1. Structural form A twin-screw consists of two screws that rotate in the same direction, and the screws cooperate with each other; while a single-screw has only one screw.

2. Synchronicity The two screws of the twin screw run at the same time, so the synchronization requirements are high. The single screw has only one screw, and the synchronization requirements are relatively low.

3. Transmission capacity The twin-screw is composed of two screws, which has stronger transmission capacity and greater torque. The single screw has only one screw and its transmission capacity is relatively weak.

B. Application of twin-screw and single-screw in industrial production Both twin-screw and single-screw are widely used in the transmission field in industrial production. Specific applications are as follows: 1. Single screw: suitable for low-speed, stable, light-load applications, such as injection molding machines, plastic sheet extruder machine, etc. 2. Twin-screw: suitable for high-speed, large-torque, variable-speed applications, such as rubber extruders, plastic sheet extruder machine, etc.