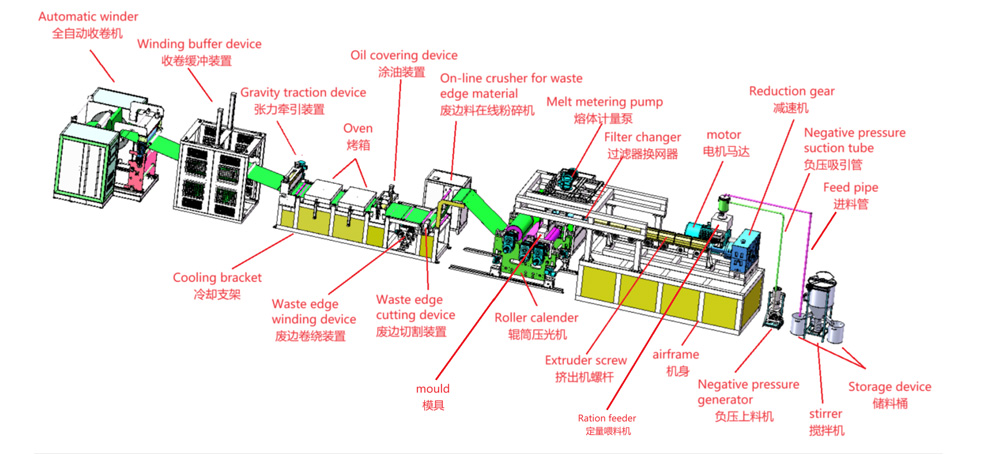

Plastic Sheet Extrusion Line Solutions

PET sheet extrusion machine, PP/PS sheet extrusion line, PP PS PE multi-layer co-extruded sheet production line, PLA sheet extrusion line. Single Screw, parallel exhaust type twin screws, planetary screws section (do not need crystallizing & drying)

Single Screw Furniture PETG Sheet Extrusion Production Line-Do Not Need Crystallizing And Drying Towers

Do not need crystallizing and drying towers to pretreat the PETG material, 100% recycled materials is ok. The forming part of the pressure roller is made of alloy steel with different thermal conductivity. Through special manufacturing technology and heat treatment process.

1, Lead Time:1-2 months after deposit confirmed

2, Price Term: FOB,EXW,CFN,CIF,etc.

3,Payments: T/T,Visa,Paypal,etc.

Advantages Of PETG Sheet Extrusion Production Line:

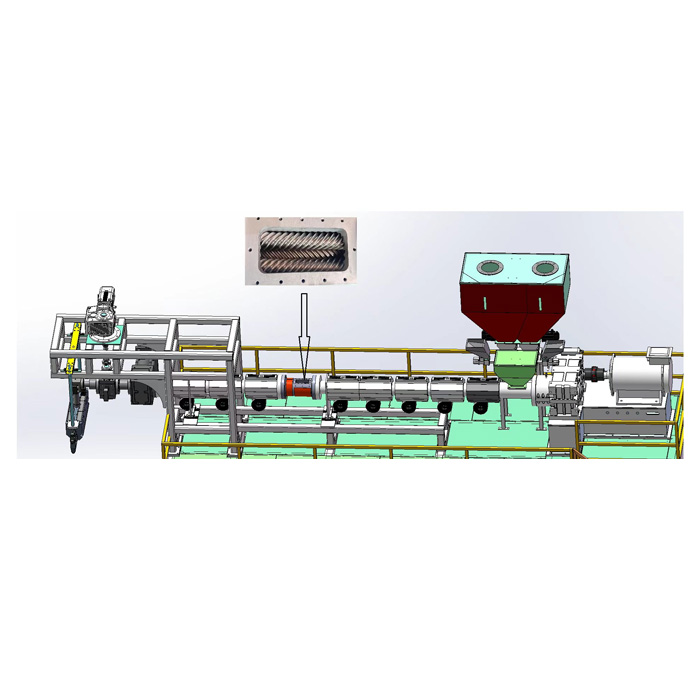

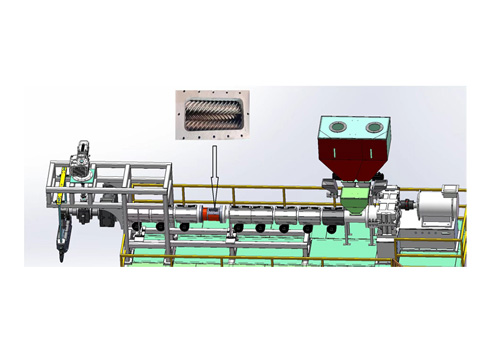

Single Screw +Planetary Exhaust Screws:

The PETG sheet extrusion production line features low energy consumption and high efficiency, utilizing special designed combination structure of single screw and planetary exhaust multi-screw. Thereby the extruded sheet not only ensures the toughness advantages of single screw production sheet, but also takes into account the advantages of multi-screw plasticization and exhaust of raw materials. At the same time, the special screw barrel structure and large area vacuum chamber + efficient vacuum device (efficient water and gas removal capacity), so compared with other models, sheet toughness is better, quality is more stable, gloss and transparency is better.

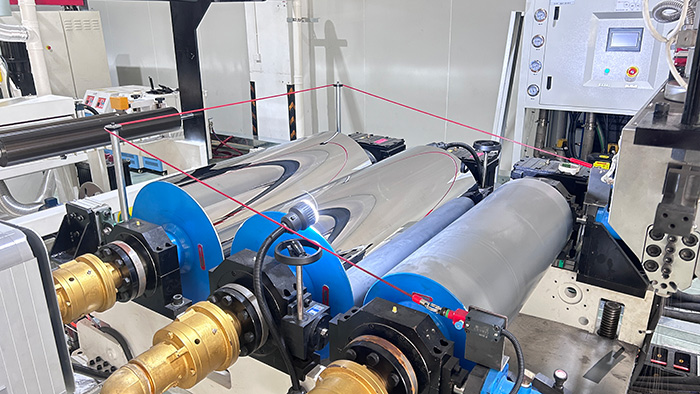

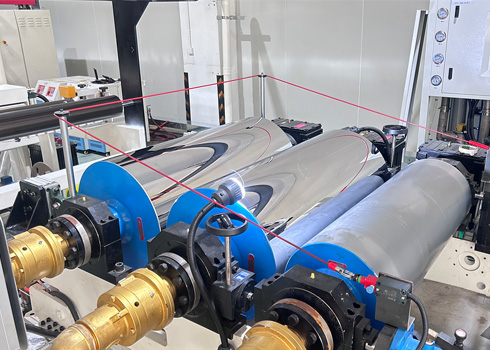

Three-roll Calender Design:

unique cross-flow channel and thin-wall design utilize PLC control to regulate the temperature and flow rate of the cooling water, ensuring uniform roller surface temperatures with a variation controlled within 1°C. This enhances the cooling effect and stabilizes product quality, increase production output.

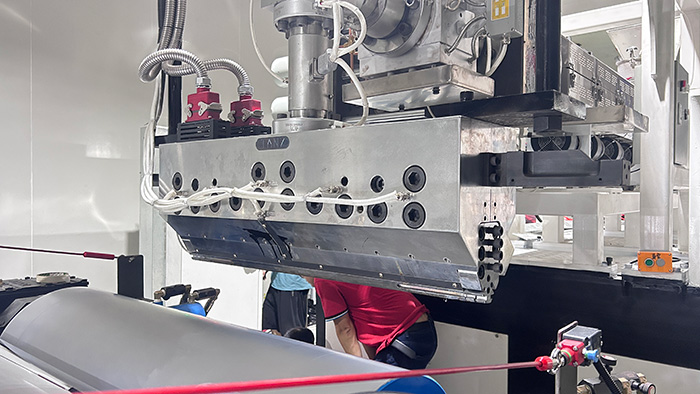

Fully Automatic Extruded Mold:

The die lip opening adjusts automatically based on feedback signals from the thickness gauge regarding film uniformity. The die head has multiple heating zones, allowing for effective and precise temperature control. The fully automatic multi-layer co-extrusion flat die, combined with thickness gauge feedback, ensures uniformity in film thickness. The product thickness variation remains within ±3%.

Sheet Production Line Online Crusher:

The edge trimming recycling system, efficient crushing and pneumatic conveying system, cyclone dust separator, and centralized feeding system save raw material costs for customers, achieving a 95% product yield.

Equipment Parameters:

- Mixing-drying Machine

- Ration Feeder

- Masterbatch Mixer

- Extruder Screw

- Hydraulic Filter Changer

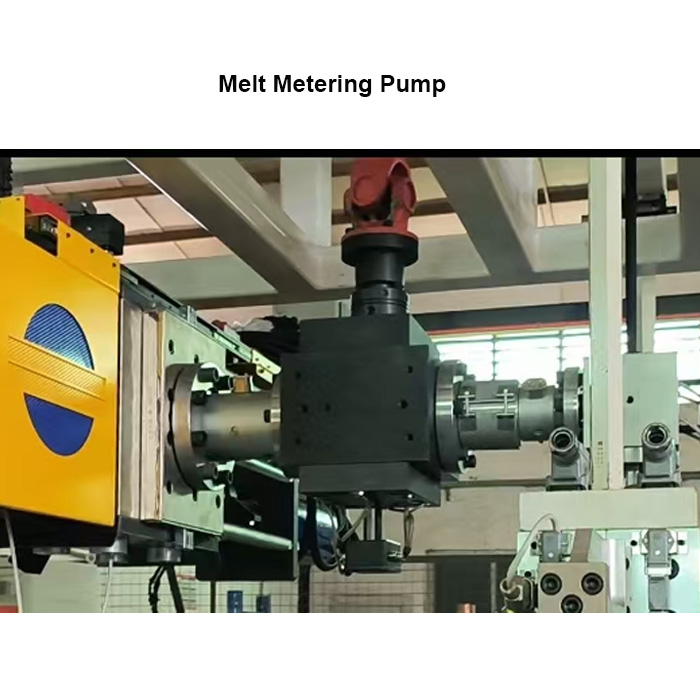

- Metering Pump

- Mould

- Three-roll Calender

- Waste Edge Cutting Device

- On-line Crusher of Waste Edge Material

- Thickness Gauge

- Corona Device

- Oil Coating Device

- Oven

- Traction Machine

- Storage Rack

- Automatic Winder

- Calender Temperature Control System

Technical Parameters:

| Model/Parameters | Complicable Material | Screw specifications | Sheet thickness (mm) | Sheet width (mm) | Maximum extrusion output (kg/h) | Installed capacity (KW) |

|---|---|---|---|---|---|---|

| TANZ-100PET | PET | Φ100 | 0.2-1.6 | ⩽850 | 200-300 | 210 |

| TANZ-120PET | PET | Φ120 | 0.2-1.6 | ⩽850 | 400-500 | 250 |

| TANZ-130PET | PET | Φ130 | 0.2-1.6 | ⩽850 | 600-700 | 435 |

| TANZ-150PET | PET | Φ150 | 0.2-1.6 | ⩽850 | 800-1000 | 460 |

| TANZ-120/65 | PET/PLA | Φ120/65 | 0.2-1.6 | ⩽850 | 550-650 | 310 |

| TANZ-150/70 | PET/PLA | Φ150/70 | 0.2-1.6 | ⩽800 | 800-1000 | 365 |

Machine Details:

Extruder

It is derived from Taiwan’s technology design, free drying and exhaust type planet type screw,which has the advantages of mandatory feeding,high speed,high production capacity , and high quality . It is suitable for 80% recycling material, maintaining the original toughness of the original sheet.

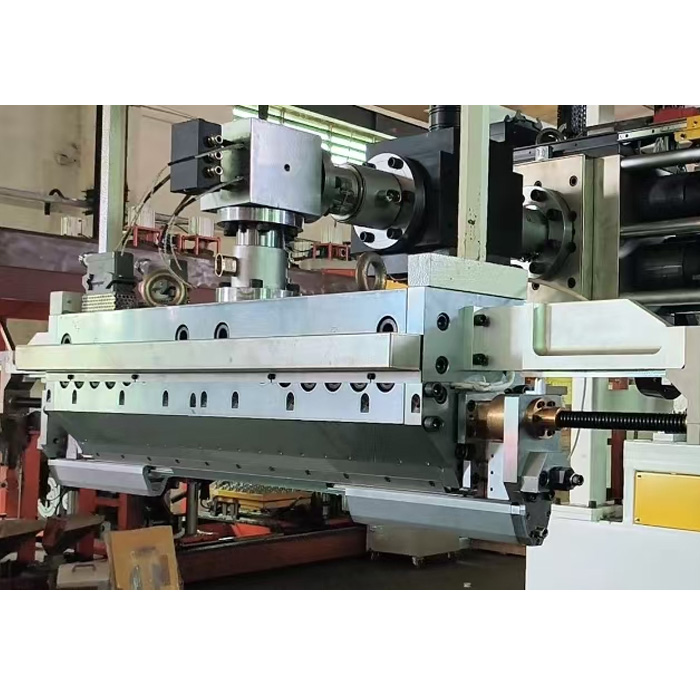

Mould

The mold is made of alloy steel, and the flow channel is chrome-plated and polished, allowing the mold width to be adjusted without stopping the machine.

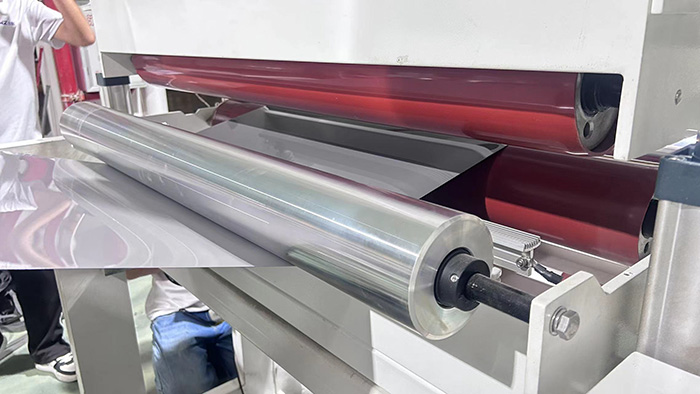

Three-roller calender

The three-roller light machine is a horizontal or vertical or 45 degree inclined design.The thickness of the sheet is automated adjustment system,The machanical roller has anti-collision protection function.The use of electronic hand wheel operations to implement the sheet specifications,which are transformed quickly and relaxed,and no tedious operations are required.The accuracy of slices is as high as 0.005mm.

Fully-auto Shaftless Winder

This is Taiz Patent shaftless winder, it can wind sheet in roll, count, cut of the sheet and change sheet roll automatically. Shaftless design, convinient to load the sheet roll materials. Therefore improve production efficiency and achive big production capacity.