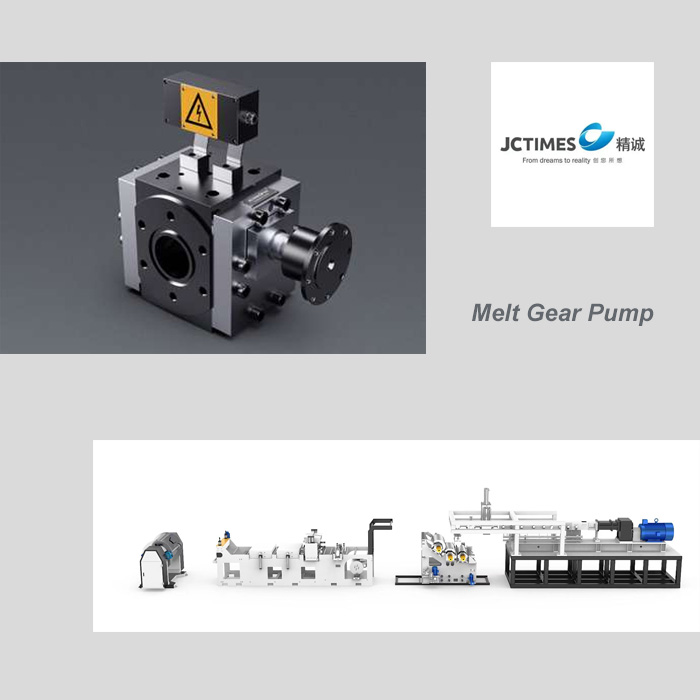

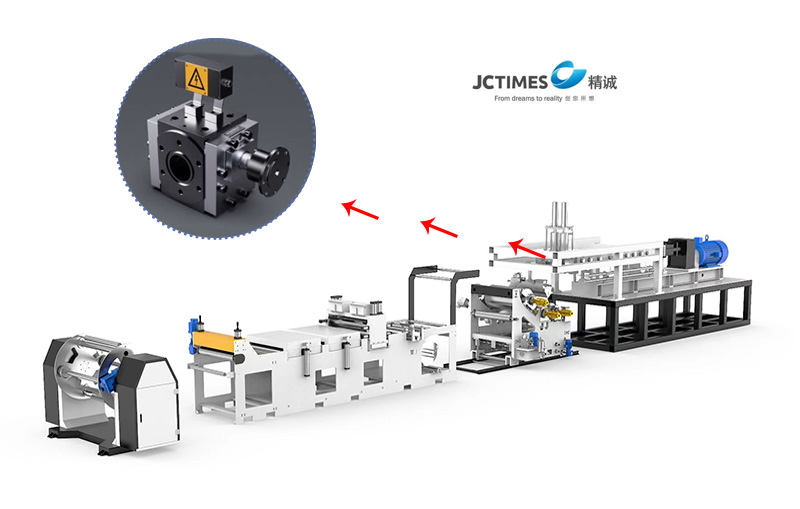

The JCTIMES melt metering pump plays a pivotal role in enhancing production efficiency and product quality in PET PP PS PLA sheet extrusion lines. Below are the detailed applications and advantages:

Opplication Overview Of JCTIMES Melt Gear Pump:

Material Conveying:

The JCTIMES melt metering pump can steadily deliver high-temperature molten plastics (such as PE, PP, PET, etc.) to sheet extrusion machines, ensuring continuity and stability in the sheet production process.

Material Conveying:

During sheet extrusion production, the melt metering pump precisely controls flow and pressure, ensuring consistent material output and preventing raw material waste or product nonconformity.

Mixing and Compounding:

In certain applications, the pump can be combined with other raw materials (such as additives and fillers) to achieve uniform mixing of the melt, thus enhancing the performance of the sheets.

Temperaturkontrolle:

These pumps are typically equipped with heating systems to maintain the appropriate temperature of the melt during transport, avoiding blockages caused by low temperatures.

Advantages In Sheet Extrusion Lines:

Increased Production Efficiency:

Stable flow and efficient conveying performance enable higher production speeds and better cycle times on the production line.

Reduced Energy Consumption:

Accurate metering and flow control minimize raw material waste while optimizing energy consumption.

Enhanced Product Quality:

Precise control over melt flow and uniform mixing improves the quality of the final sheets, reducing the likelihood of defects and nonconforming products.

User-Friendly Operation:

The relatively simple operation convenience allows workers to easily manage and maintain the production process.

Strong Compatibility:

The JCTIMES melt metering pump is widely compatible with various plastic materials, allowing manufacturers to select different raw materials according to their needs.

Conclusion:

In summary, the application of JCTIEMS melt metering pumps in sheet production lines significantly enhances production efficiency and product quality, bringing higher economic benefits to processing plants. If you have more specific questions or need deeper technical details, feel free to ask!