The Evolution of Thermoforming: Exploring Positive and Negative Pressure Multi-Station Integrated Thermoforming Machines

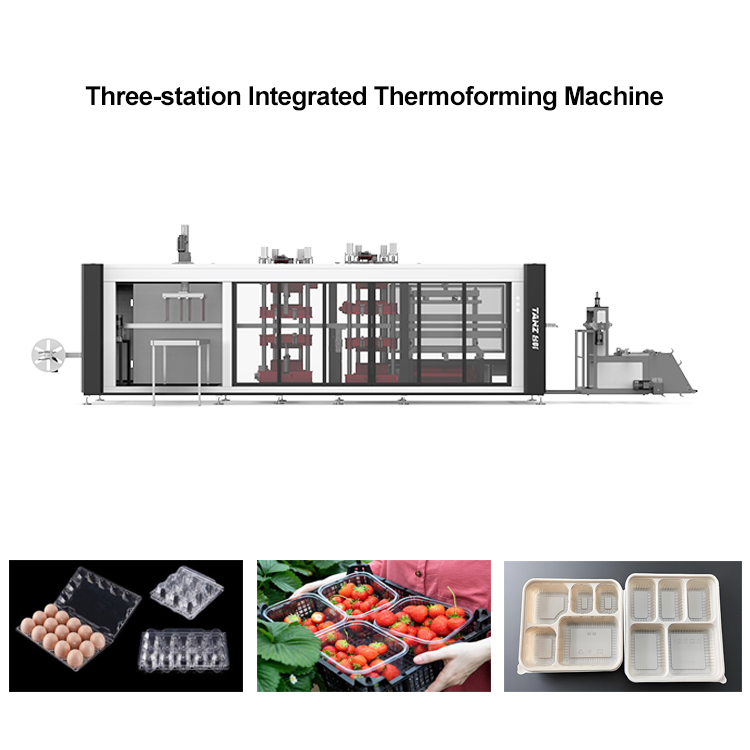

Thermoforming is a widely used manufacturing process that involves heating a plastic sheet to a pliable forming temperature, shaping it into a specific form using a mold, and trimming it to create a usable product. Over the years, advancements in thermoforming technology have led to the development of highly efficient and automated machines that cater to diverse industrial needs. Among these innovations, the Tz-Machinery Positive and Negative Pressure Multi-Station Integrated Tiefziehmaschine stands out as a game-changer in the industry. This article delves into the technical aspects, advantages, and unique features of this cutting-edge machine, highlighting why it is a top choice for manufacturers worldwide.

What is the Tz-Machinery Positive and Negative Pressure Multi-Station Integrated Thermoforming Machine?

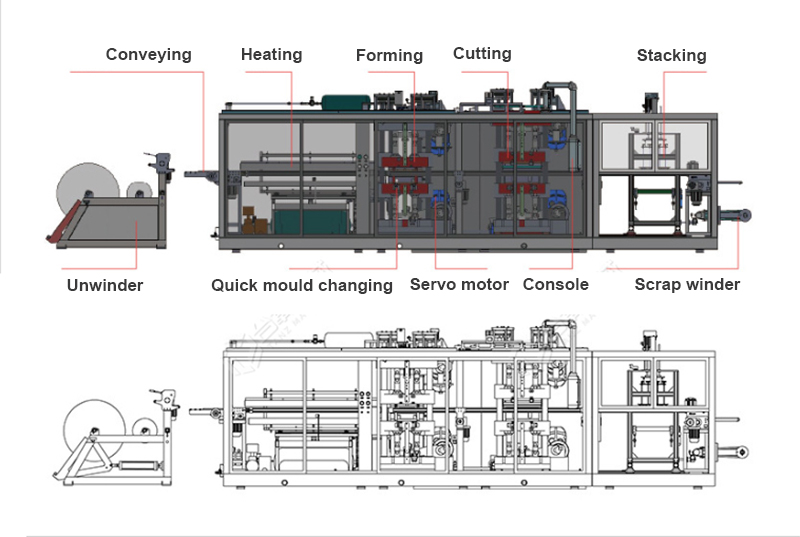

The Tz-Machinery thermoforming machine is a state-of-the-art solution designed for high-efficiency production of thermoformed products. It integrates positive and negative pressure forming techniques, enabling the creation of complex and precise shapes with ease. The machine is equipped with multiple stations, allowing for simultaneous operations such as heating, forming, cutting, and stacking, which significantly enhances productivity.

As a leading thermoforming machine manufacturer, Tz-Machinery has engineered this machine to meet the demands of modern manufacturing, offering a seamless blend of automation, precision, and versatility. Whether you are producing packaging, automotive components, or consumer goods, this machine is designed to deliver exceptional results.

Key Advantages of the Tz-Machinery Thermoforming Machines:

1. Fully Automatic Integrated Design: Convenient to Operate, Saves Labor

One of the standout features of the Tz-Machinery thermoforming machine is its fully automatic integrated design. This design eliminates the need for manual intervention at various stages of the production process, reducing labor costs and minimizing the risk of human error. Operators can easily control the machine through an intuitive interface, ensuring smooth and efficient operation.

The automation extends to all stages of the thermoforming process, including sheet feeding, heating, forming, cutting, and stacking. This not only speeds up production but also ensures consistent quality across all products.

2. Unique T-Shape Mold Platform Design

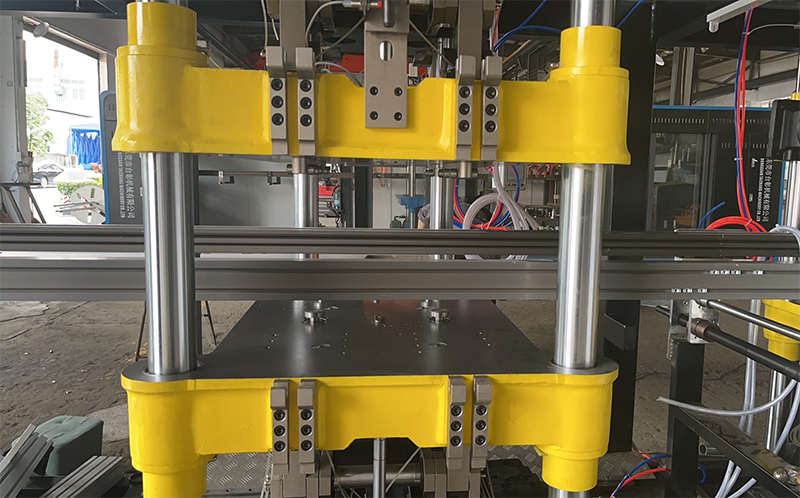

The Tz-Machinery thermoforming machine incorporates a unique T-shape mold platform design, which sets it apart from conventional machines. This innovative design ensures that both the forming mold and cutting mold can be inserted into the mold platform with ease. The T-shape configuration provides ample space for mold installation and adjustment, reducing downtime during mold changes.

This feature is particularly beneficial for manufacturers who frequently switch between different product designs. The ease of mold insertion and removal enhances flexibility and allows for quick adaptation to changing production requirements.

3. Slot Design for Forming and Cutting Mold Platform

Another notable feature of the Tz-Machinery thermoforming machine is the slot design for the forming and cutting molds. This design allows for precise alignment and secure placement of the molds, ensuring accurate forming and cutting of the plastic sheets. The slots also facilitate quick mold changes, further improving operational efficiency.

The slot design is especially advantageous for producing intricate and high-precision products, as it minimizes the risk of misalignment and ensures consistent product quality.

Technical Specifications and Features:

1. Multi-Station Design: The machine features multiple stations for heating, forming, cutting, and stacking, enabling continuous and efficient production.

2. Positive and Negative Pressure Forming: Combines both techniques to achieve superior forming accuracy and versatility.

3. High-Speed Operation: Designed for high-speed production, making it ideal for large-scale manufacturing.

4. Energy Efficiency: Poiont to point temperature control, control every ceramic heating part precisely according to different material heating requirement. Incorporates energy-saving technologies to reduce power consumption and operational costs.

5. User-Friendly Interface: Equipped with an intuitive control panel for easy operation and monitoring.

Applications of the Tz-Machinery Thermoforming Machine:

The versatility of the Tz-Machinery thermoforming machine makes it suitable for a wide range of applications, including:

Packaging: Production of trays, clamshells, blisters, and other packaging components.

Consumer Goods: Creation of household items, toys, and electronics tray.

Medical: Production of sterile packaging and medical device tray.

Why Choose Tz-Machinery as Your Thermoforming Machine Manufacturer?

Tz-Machinery has established itself as a trusted name in the thermoforming industry, known for its commitment to innovation, quality, and customer satisfaction. The Positive and Negative Pressure Multi-Station Integrated Thermoforming Machine is a testament to the company’s expertise and dedication to advancing thermoforming technology.

By choosing Tz-Machinery, you gain access to:

Cutting-edge thermoforming solutions tailored to your specific needs.

Reliable and durable machines built to withstand rigorous industrial use.

Comprehensive support, including installation, training, and after-sales service.

Conclusion

The Tz-Machinery Positive and Negative Pressure Multi-Station Integrated Thermoforming Machine represents the pinnacle of thermoforming technology. With its fully automatic design, unique T-shape mold platform, and innovative slot design for molds, this machine offers unparalleled efficiency, precision, and flexibility. Whether you are a seasoned manufacturer or new to thermoforming, this machine is designed to meet your production needs and exceed your expectations.

As the demand for high-quality thermoformed products continues to grow, investing in advanced machinery like the Tz-Machinery thermoforming machine is a strategic move that can give your business a competitive edge. Explore the possibilities and elevate your production capabilities with Tz-Machinery today.